Manufacturing-X has quickly moved from concept to priority on the German industrial agenda. At its core, the initiative is about rethinking industrial data sharing. And the emphasis is on relevant, representative data that enables collaboration while preserving security, sovereignty, and trust.

Enabling secure data exchange in Manufacturing X requires robust data collection pipelines, added IoT and wireless capabilities, and, above all, cybersecurity by design. From remote wind farms to legacy production lines, the main challenge remains the same: deciding what can be shared, what must remain protected, and how to manage both across legacy systems and highly regulated environments. And how manufacturers resolve this trade-off will shape the success of Manufacturing-X in practice.

What Manufacturing-X means

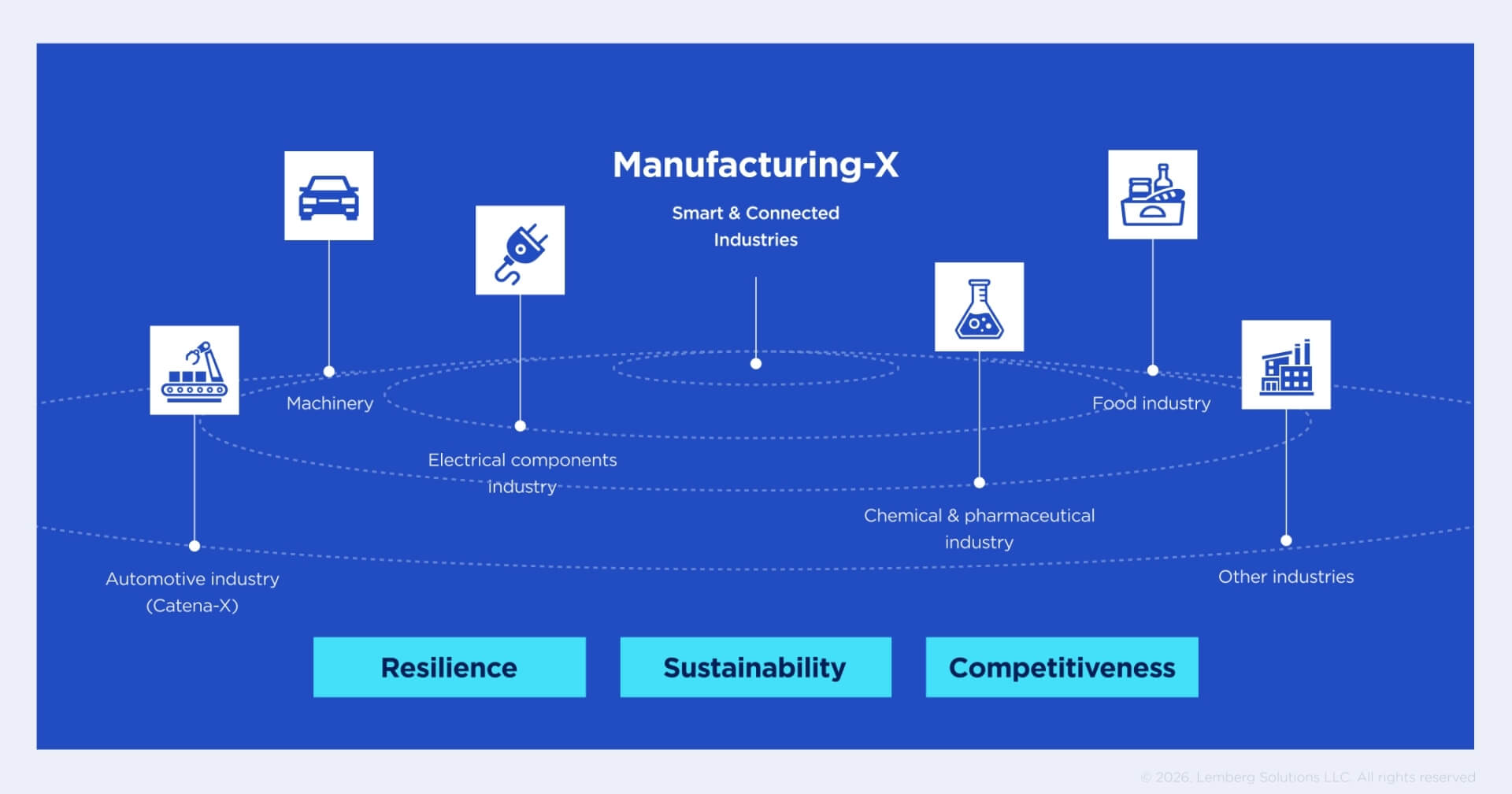

Manufacturing-X is a German government-backed initiative launched to create a single open digital ecosystem for all manufacturers, streamlining processes and enabling new digital business models. The initiative aims to strengthen the competitiveness, resilience, and sustainability of industrial value networks by enabling interoperable data sharing across enterprises and industrial sectors.

The context of data exchange depends on the business case: whether operating wind turbines dispersed across remote fields, legacy production lines never built for seamless connectivity, or modern logistics systems. At the same time, industrial data rarely resides in a single place; it is scattered across ERP, MES, WMS, CRM, and other systems, deployed in on-premises, cloud, multi-cloud, and hybrid environments. Such conditions make a unified data ecosystem possible only through well-planned integration and balanced decision-making.

The “X” in Manufacturing-X stands for exchange — the controlled sharing of data and collaboration not only between companies within the same industry, but also across industrial sectors.

The Manufacturing X initiative includes various industry-specific projects, such as Catena-X for the automotive industry, Factory-X for mechanical engineering, Robot X, and energy data X, etc. And it is being shaped by Germany’s largest industrial players. Companies such as Siemens, Bosch, SAP, Volkswagen Group, BMW Group, and Mercedes-Benz Group bring the backbone technologies for automation, industrial software, and enterprise integration. Together, these companies illustrate that Manufacturing-X is driven by real industrial needs. They engage manufacturers across Germany to join the initiative.

Data sovereignty as the foundation of industrial digitalization

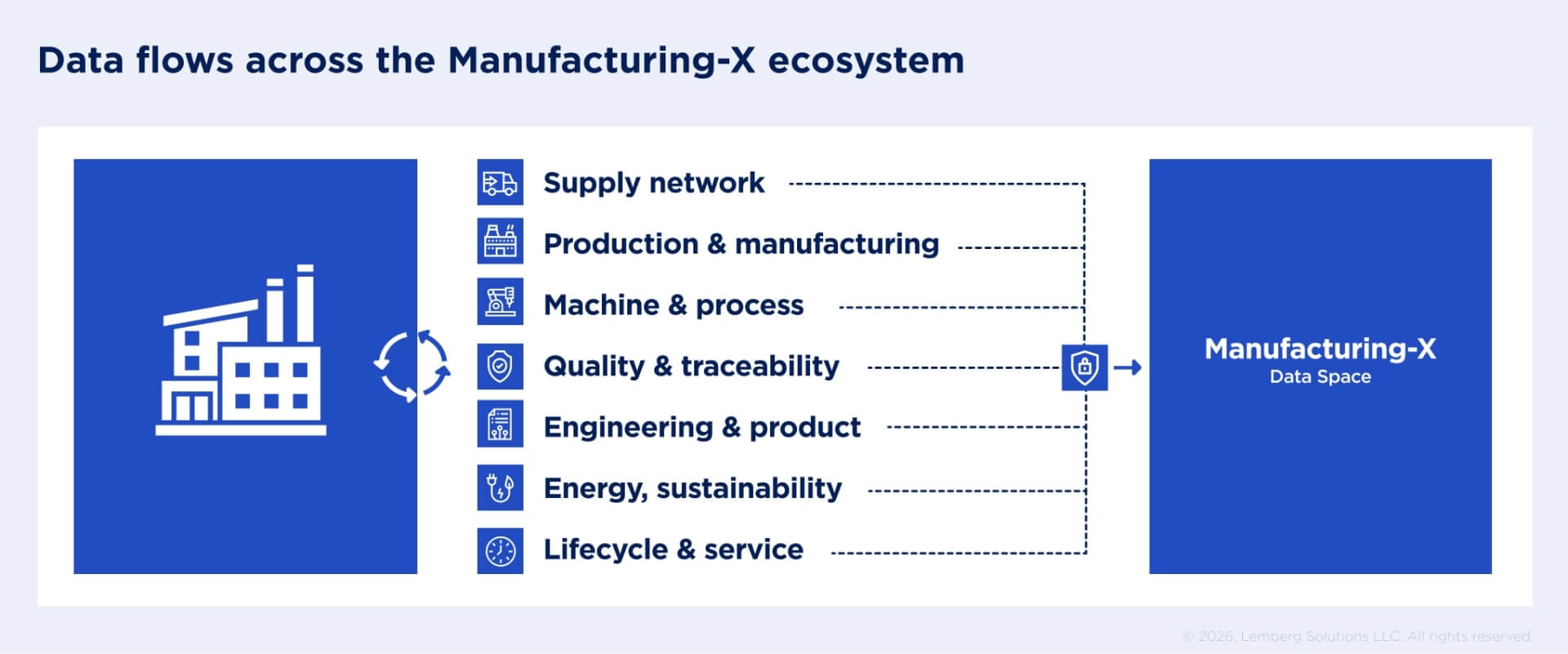

Data is the raw material for Manufacturing X. Industrial data is available in large quantities in every company and includes insights from production and manufacturing, specific processes, machines and their components, engineering & product data, supply networks, energy sustainability.

Most manufacturing data is highly sensitive and reveals how factories operate, where efficiencies are achieved, and where weaknesses exist. It is not surprising that manufacturers are unwilling or highly cautious about sharing it. Here comes the core dilemma: balancing the need for data exchange against the critical risks of losing intellectual property and security. And this dilemma is partially addressed with the idea of data sovereignty.

Data sovereignty provides the foundation for trustful and collaborative data sharing. It transforms data from a siloed risk into a secure, shared asset, establishing the necessary trust for companies to collaborate across value chains without losing control over their intellectual property. From a legal perspective, it also ensures that data is stored and processed in accordance with the laws and regulations of the country in which it resides.

How to ensure secure and interoperable data sharing in Manufacturing X

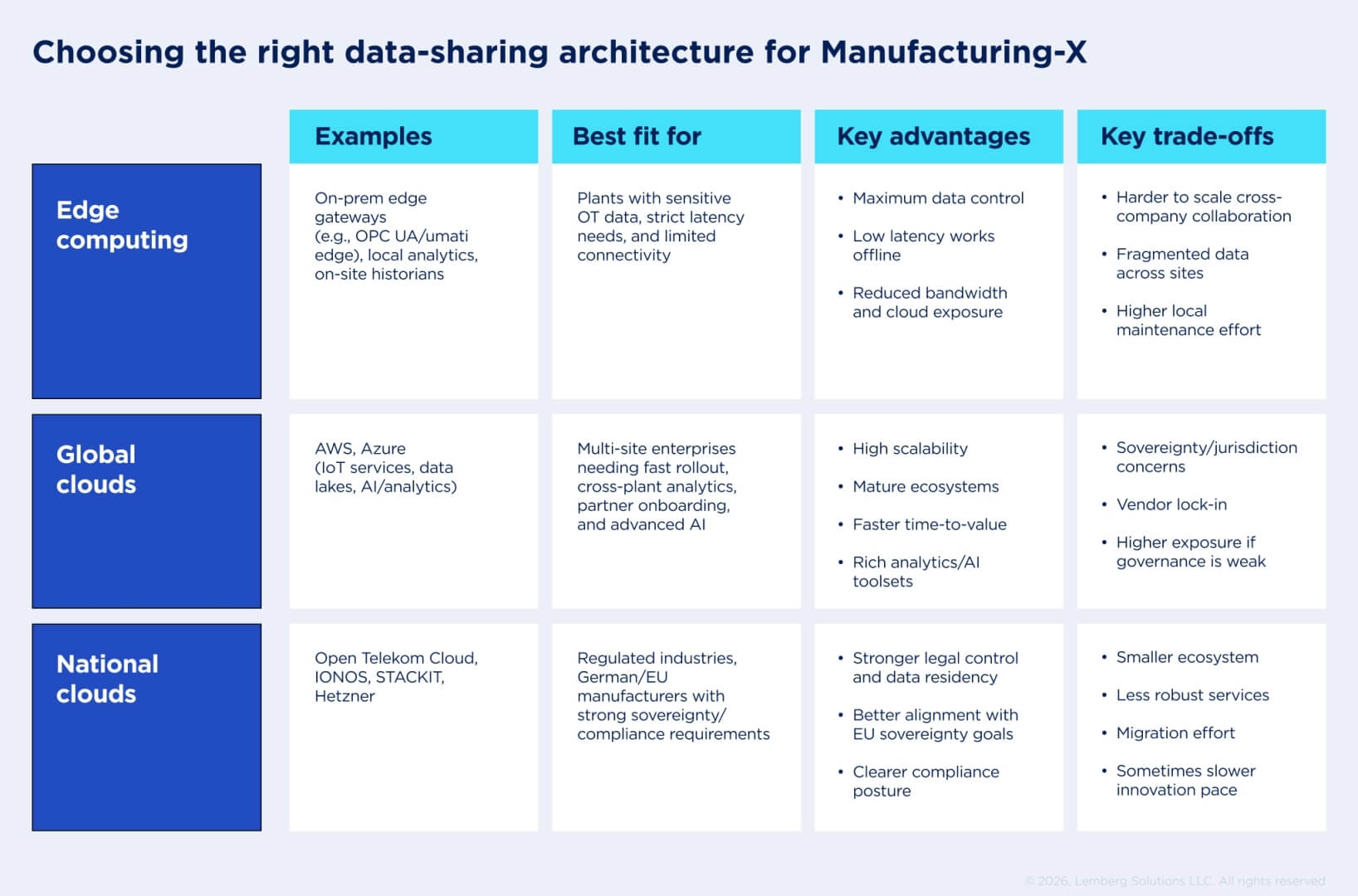

There is no universal data-sharing architecture when looking for the right balance between the level of data exchange, security and interoperability. The choice always depends on business needs and a continuous trade-off between value and risk. As seen in most industries, companies must decide which data to keep local, which to share, and which risks they are willing to accept in exchange for faster insights and collaboration.

In practice, companies evaluate three dominant options: global hyperscaler clouds, sovereign/national clouds, and edge-centric approaches, each offering a different balance between scalability, sovereignty, and operational control.

Edge computing: maximum data control, limited scalability

Many German manufacturers still operate on legacy OT and production systems that were never designed for connectivity or large-scale data exchange. Integrating these systems is a complex task and often requires edge computing to preprocess, filter, and protect sensitive data before it leaves the factory. Edge computing keeps sensitive production and process data on-site or near the machine, reducing exposure and latency. For manufacturers, it provides data availability along with real-time control and strict protection of production know-how and other ultra-sensitive data.

The limitation is that edge alone does not enable full-scale Manufacturing-X collaboration, as it often allows the exchange of only selected datasets. Participation in cross-company data spaces still requires interoperable cloud platforms and standardized data interfaces.

Global cloud providers (AWS, Azure): scalability and maturity vs. sovereignty and dependency risks

Manufacturers that modernize their systems rely on global cloud providers such as Amazon Web Services and Microsoft Azure. These global hyperscalers are chosen for their speed, scalability, and mature analytics and AI ecosystems. In the context of Manufacturing-X, where fast rollout, cross-plant analytics, and advanced AI use cases are critical, global clouds offer clear operational advantages.

At the same time, however, many German manufacturers remain cautious. Concerns around data sovereignty, long-term vendor lock-in, and legal exposure under non-European jurisdictions continue to shape cloud decisions. In response, AWS is launching its European Sovereign Cloud model with EU-based operations and EU residency controls. Microsoft completed its EU Data Boundary and announced broader sovereign cloud capabilities for Europe.

Nevertheless, technical safeguards alone are not sufficient. Even with EU-specific sovereignty constructs, manufacturers must still establish strong governance models to ensure that shared industrial data remains fully under their authority within Manufacturing-X data spaces.

National and sovereign clouds: stronger control with ecosystem trade-offs

National and EU-focused clouds, such as Open Telekom Cloud, IONOS, STACKIT, Hetzner, and Gridscale, have strong German-first positioning and are often selected when sovereignty assurance is a board-level requirement. These platforms align well with the Manufacturing-X initiative, especially for regulated industries and conservative supply networks. Furthermore, they are typically positioned around EU/Germany compliance and certifications. For example, Open Telekom Cloud publicly positions services around sovereignty and has pursued GAIA-X compliance for specific services.

However, manufacturers that choose sovereign cloud providers face trade-offs, such as typically a smaller ecosystem and fewer advanced services than global hyperscalers. At the same time, they are less mature in specialized analytics, and AI workloads are integrated selectively. As a result, sovereign clouds are frequently used as the collaboration backbone, while specialized analytics or AI workloads are integrated selectively.

Federated learning: shared intelligence without sharing raw data

To leverage collaborative data spaces while keeping the most sensitive data on-site, German manufacturers use hybrid approaches. In this context, federated learning is an attention-grabbing approach. The reason is that federated learning directly addresses the need to collaborate on insights while keeping sensitive data under control. Instead of moving raw production or supply-chain data to a central cloud platform, federated learning allows companies to train shared models locally and exchange only model updates or aggregated results.

From a business perspective, this approach aligns naturally with how German industrial ecosystems operate. Many manufacturers are willing to collaborate on outcomes, such as better quality prediction, more accurate demand forecasts, or improved predictive maintenance, but are reluctant to expose the underlying data that reflects proprietary processes, machine tuning, or supplier performance. Federated AI makes this separation possible.

Turning Manufacturing-X into value: key industrial use cases

At the same time, the final goal of the Manufacturing X initiative is not abstract data exchange, but measurable improvements in availability, efficiency, resilience, and time-to-decision across factories and supply networks.

Industrial IoT

In Manufacturing-X, industrial IoT serves as the data-capture layer, turning raw machine signals into reusable, interoperable datasets across plants. A typical industrial IoT architecture spans the factory floor, where:

- Machines generate telemetry

- Edge components preprocess data

- Cloud IoT services handle secure data handling

- Insights trigger alerts, dashboards, or automated actions

An industrial IoT platform acts as a bridge between operational technology and the cloud. Platforms such as Microsoft Azure and Amazon Web Services follow this model, combining mature IoT services with strong edge computing support to balance scalability with latency and bandwidth constraints. A prominent example is the Volkswagen Industrial Cloud, built on AWS to connect machines, plants, and systems across more than 100 factory sites, standardizing manufacturing and logistics data use cases at a global scale.

This illustrates why hyperscaler-based architectures are often chosen in Manufacturing-X scenarios that demand rapid rollout, cross-plant analytics, and shared data products despite the ongoing trade-offs around data sovereignty and long-term dependency.

Predictive maintenance

Predictive maintenance is one of the clearest use cases for Manufacturing-X. By combining machine condition data across plants, suppliers, or comparable equipment, manufacturers can identify failure patterns earlier and significantly reduce unplanned downtime.

To address data security and intellectual property concerns, data exchange for predictive maintenance does not necessarily require exposing all machine “secrets.” Instead, manufacturers can opt for edge-first approaches to keep sensitive raw signals local while sharing only derived features, alerts, or health indicators needed to coordinate service, spare parts, and uptime across companies.

In practice, sensor-based condition monitoring is increasingly used to enable continuous asset observation across distributed environments. In such setups, federated AI plays a critical role by enabling decision-makers to improve prediction models without exchanging raw sensor data or machine parameters.

Robotics, automation, and AGV systems

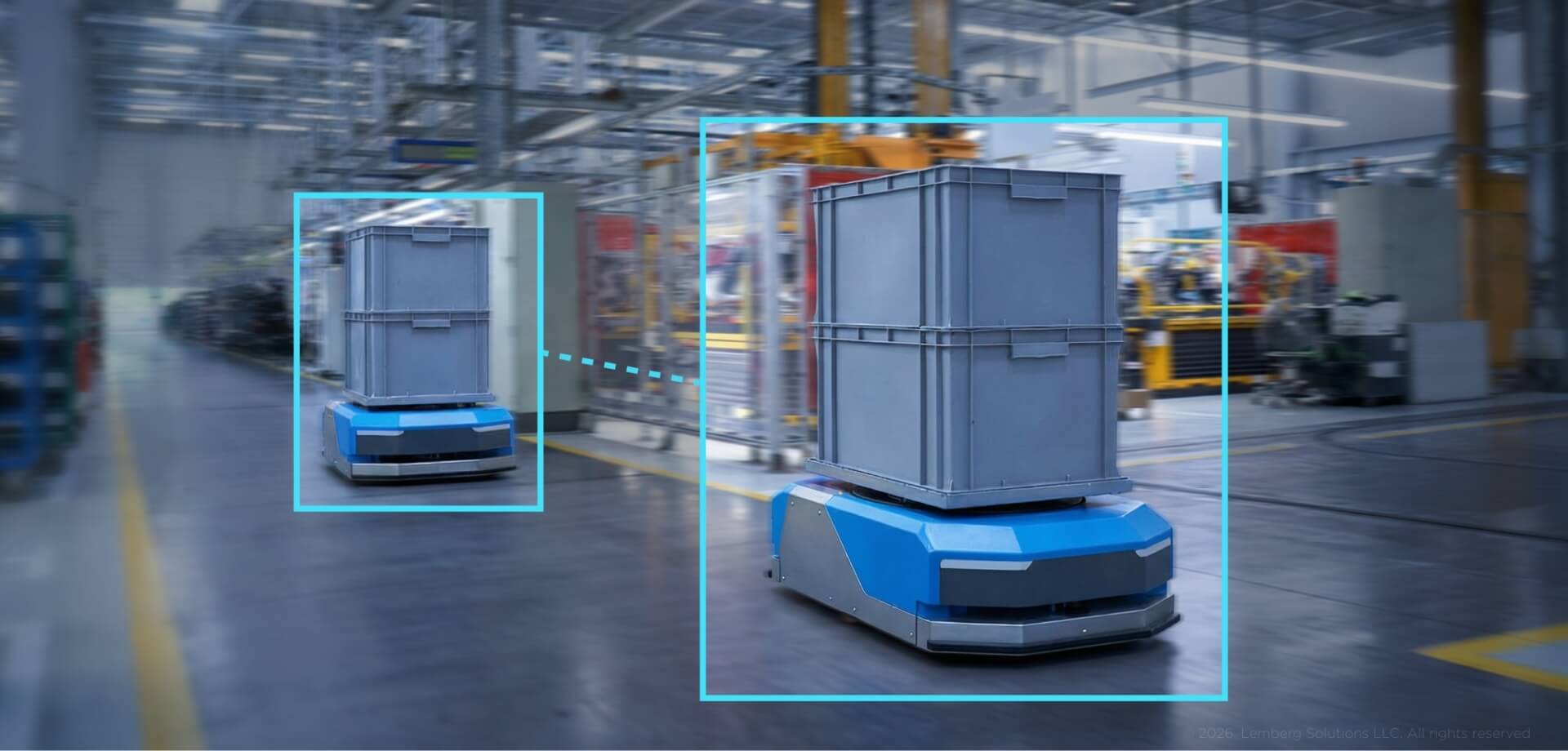

Robotics and AGV systems depend on precise, real-time data from production, logistics, and warehouse environments. Manufacturing-X enables these systems to operate beyond isolated factories by allowing controlled data exchange across sites and partners. A prominent AGV use case is BMW’s IDEALworks GmbH, which provides autonomous logistics robots and management software. These robots navigate autonomously using onboard sensors and local edge controllers, exchanging real-time data with fleet management systems for task assignment, traffic coordination, and safety.

Digital twins and simulation with NVIDIA Omniverse

Digital twins turn Manufacturing-X data into actionable insight by creating shared, virtual representations of products, production lines, and entire factories. Platforms such as NVIDIA Omniverse enable real-time simulation and collaboration across engineering, production, and operations. Omniverse brings together data from CAD and PLM systems, IoT sensors, and enterprise platforms into a unified 3D environment, allowing teams to jointly plan layouts, validate automation logic, and test AI-driven vision or robotics use cases. This makes it a natural enabler for Manufacturing-X scenarios that require collaboration without unrestricted data exposure.

A representative example is the BMW Group’s FactoryExplorer, built on NVIDIA Omniverse. BMW uses the platform to collaboratively plan factory layouts and simulate robotics and computer-vision applications before deployment, reducing risk and accelerating ramp-up. Architecturally, this approach combines local and edge data feeds with cloud-based collaboration, illustrating the Manufacturing-X principle of share what is necessary, keep control of what is critical.

Lemberg Solutions' place in the Manufacturing X initiative

At Lemberg Solutions, we support manufacturers by designing and building the technical foundations required for modern, data-driven production. Lemberg Solutions delivers industrial IoT services that connect machines, edge systems, and cloud platforms to enable secure data collection, processing, and selective sharing across sites and stakeholders.

For organizations concerned about data sovereignty, our experts design secure, scalable cloud architectures on global hyperscalers such as AWS and Azure, as well as on local providers such as Open Telekom Cloud and STACKIT. Our experts help teams modernize legacy setups step by step and implement solutions for condition monitoring, predictive maintenance, and operational optimization. Throughout this process, we focus on building systems that are scalable, secure, and maintainable, so manufacturers can use their data effectively today without limiting future architectural choices.