Digitalization in the automotive industry reshapes traditional business approaches and augments industry capabilities. Uniting advanced technologies and automotive engineering boosts the development of data-driven solutions and connected systems with improved operational efficiencies. Automotive companies embrace digital transformation to optimize manufacturing processes, refine supply chain management, and redefine user experiences.

In this article, you will learn the benefits of automotive digital transformation, its use cases, challenges for businesses, and key trends.

What is digital transformation in the automotive industry

Digital transformation in the automotive industry helps manufacturers to change their business processes, improve supply chain, enhance production, and increase passenger and vehicle safety. Embracing digital transformation, automotive companies can keep leading positions in the market and attract new customers.

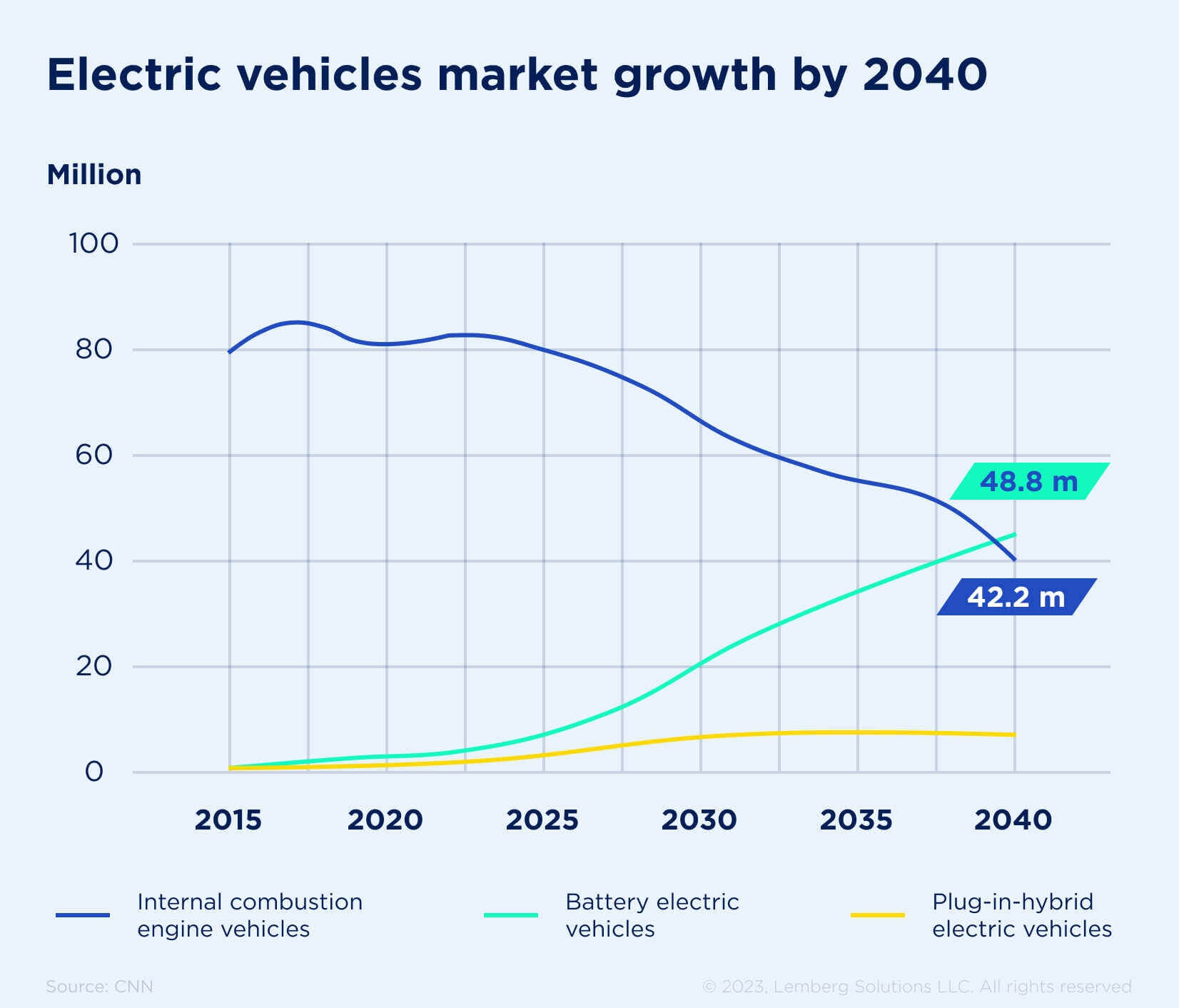

Recently, battery prices have declined, which means that automotive organizations can increase the production of electric vehicles, fully adopting digital transformation. Electric cars become more popular, and more investors are willing to support this trend. Researchers predict that by 2040, electric vehicle sales will outgrow diesel and gasoline car sales.

5 benefits of automotive digital transformation

Embracing digital transformation within the automotive industry enhances operational efficiency, boosts innovation, and enables the development of smart and connected vehicles. The implementation of digital transformation optimizes manufacturing processes and revolutionizes the driving experience through such solutions as advanced driver assistance systems (ADAS) and infotainment systems. Digital transformation plays a pivotal role in meeting evolving consumer demands, contributing to sustainable development, and staying competitive in a rapidly changing market.

Here are five main advantages automotive companies will gain from the digital transformation of their businesses and manufacturing operations.

1. Online presence

Establishing an online presence for automotive solutions boosts broader outreach for retailers. In today's digital era, the majority of clients can be found online. Employing the right tools and strategies to connect with a vast online audience will bring increased attention to your product and, thus, business growth. Note that 70% of car owners start vehicle shopping online instead of dealerships.

2. Improved customer experience

More and more automotive companies integrate built-in connectivity and infotainment systems into their vehicles, enhancing the overall in-car experience for end users. Nearly nine out of ten connectivity car owners are satisfied with using such features as voice-activated control, vehicle connection to the Internet, mobile apps for cars, and in-vehicle virtual personal assistants.

3. Better product quality

With innovative automated production systems, manufacturers are more likely to notice any quality deviations during the manufacturing process due to simplified real-time data collection. These systems also help avoid reclamations and huge financial losses.

4. Automated routine tasks

While transforming business, manufacturers can integrate real-time data monitoring and analysis to enhance resource utilization and increase productivity. With automotive digital transformation, they can help employees prevent machinery failures and minimize any health risks connected to production.

5. Supply chain optimization

By implementing technologies that perform analysis of large datasets, manufacturers will identify patterns and trends. Using predictive analytics helps to anticipate demand fluctuations, optimize inventory levels, and enhance production planning, minimizing the risk of overstocking or stockouts. This way, businesses will get a streamlined and error-free production line. Another way digital transformation can help optimize supply chains is by monitoring supplier quality with AI. For instance, Audi, Porsche, and Volkswagen apply an AI solution that collects public news written in more than 50 languages. This solution identifies whether suppliers violate any sustainability regulations, which helps automotive companies choose the best partners.

Digital transformation use cases in the automotive industry

Some automotive companies have already embraced digital transformation to gain a competitive edge. Read below to learn how manufacturers apply modern technologies to build more successful businesses.

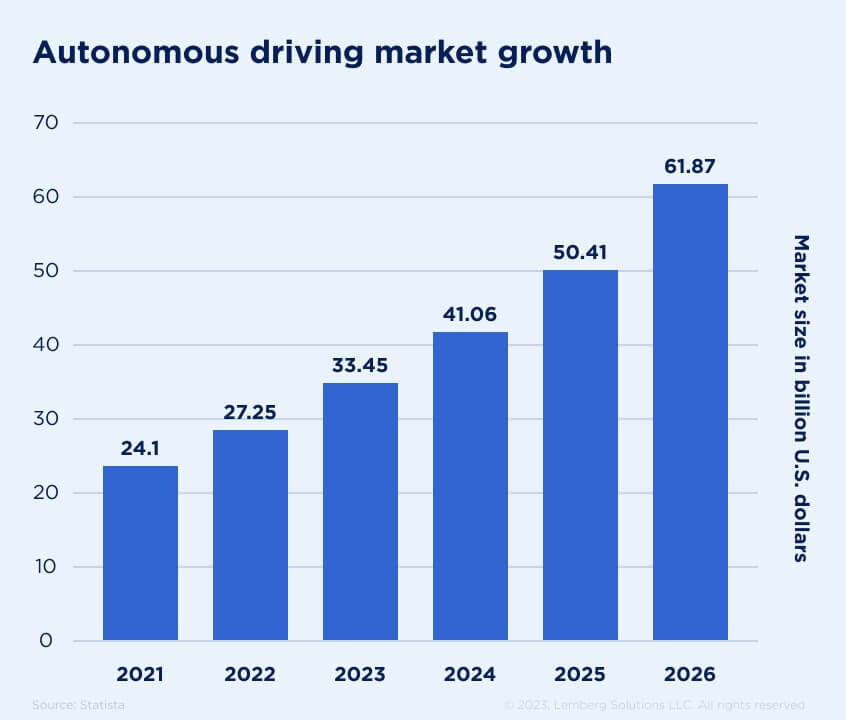

Autonomous driving

The production of autonomous vehicles is expected to increase globally. The experts predict market growth to approximately $62 billion in 2026. Enabling cars to navigate autonomously and facilitating a hands-free approach for drivers to effortlessly reach their destinations was especially successful for Tesla. Their autonomous cars caused a shift in the market, and numerous manufacturers followed their example, including Mercedes-Benz, Nissan, and Toyota. Despite all the buzz around self-driving cars, there have been lots of instances of automated self-driving cars creating traffic issues.

AI-based car design

Digital transformation in automotive manufacturing enables businesses to leverage AI for new model designs. Using machine learning, manufacturers collect historical data from previous models. AI algorithms analyze it to provide insightful recommendations for upgrading designs. Recently, manufacturers started to use ML models to create new designs and predict their attractiveness to customers since an enhanced aesthetics of the vehicle design increases sales by 30%. This way, manufacturers reduce costs spent on design creation.

Predictive car maintenance

The usage of AI algorithms for vehicle maintenance through real-time data analysis will change the automotive industry. By tracking the current performance metrics of the vehicle, manufacturers can identify and prevent potential issues. Predictive vehicle maintenance gains momentum in race cars. Manufacturers integrate it into sports cars to analyze their performance and prevent collisions during the race. Car maintenance technology will more likely be integrated into other vehicles after manufacturers check its full potential on the racing field.

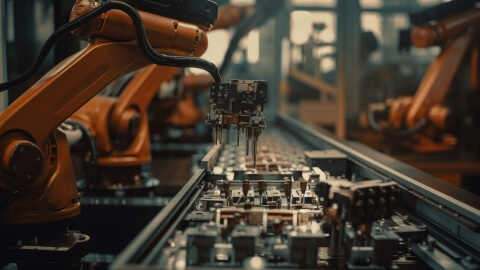

Automated manufacturing

Digital transformation in the automotive industry allows optimization of manufacturing processes. The integration of robotics and automation has become common within vehicle companies. Leveraging innovative technologies enables efficient equipment monitoring, facilitating the identification of system errors before they cause any damage. Automotive companies apply collaborative robots that work on production lines and perform high-risk tasks, while engineers can focus on more valuable and safe solutions.

Revolutionizing the supply chain

Real-time data collection comes in handy for optimizing a supply chain. Leveraging AI-empowered sensors, manufacturers revolutionize procurement management in the automotive industry. ML algorithms predict demand for vehicle components, helping to decide how many to order and where to ship them. This optimizes production costs and decreases wait times.

Chatbots

As a part of automotive digital transformation, chatbots are pivotal tools, extending beyond traditional customer interaction. These intelligent virtual assistants assist in user support, promptly addressing queries and even contributing to sales augmentation. Incorporating chatbots into the automotive industry introduces an additional layer of interaction, enhancing customer engagement and facilitating seamless communication. Whether it's guiding users through vehicle characteristics or providing real-time assistance, chatbots contribute to an elevated user experience within the automotive field.

AI has become an integral part of digital transformation within the automotive industry. ML algorithms help manufacturers collect real-time data, interact with customers, and design new car models.

Challenges of digital transformation in automotive

Any transformation is a complex process and requires a thoughtful approach. In the case of the automotive industry, companies need to change numerous operations, starting from business management to production. Here are the main challenges automotive manufacturers face when implementing digital transformation.

Lack of software development expertise

According to the Perforce Software report, 17% of automotive companies face difficulties with educating talent in 2023. The introduction of digital transformation means the development of innovative tools that engineers need to use for better vehicle performance. At Lemberg Solutions, embedded experts always stay up to date with market trends and hone new skills. Check out our automotive projects.

Compliance with new industry standards

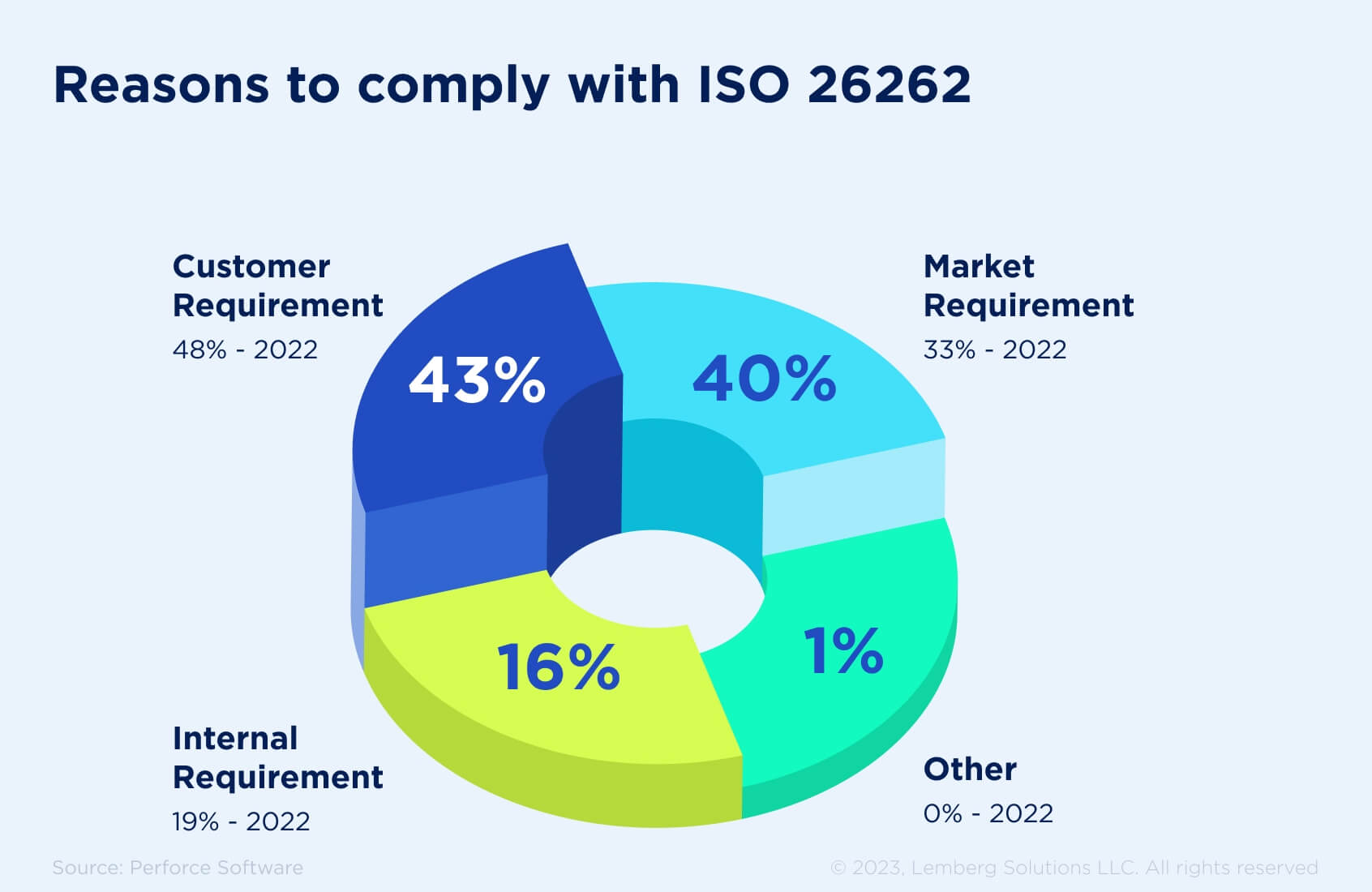

Safety has always been a major concern within automotive manufacturing, with ISO 26262 being a central functional safety standard. That is why automotive organizations seek to comply with ISO 26262 to make their products market-ready and gain a competitive edge. Automotive engineers should also consider ASPICE (Automotive Software Process Improvement and Capability Determination) framework, which ensures that the solution is reliable and efficient. Our embedded team can help you with system architecture design, digital cockpit, infotainment systems, electronic control units, and ASPICE / ISO 26262 consulting since we follow all regulations and best practices.

Capital allocation

Embarking on digital transformation in the automotive industry requires substantial financial commitments. The uncertainty surrounding the return on investment (ROI) for new technology integration is a challenge, introducing financial risk for investors.

Data privacy

As companies within the automotive industry collect vehicle and driver data to enhance vehicle characteristics and innovate their products and services, the question of data security becomes more important. Manufacturers need to find new ways to ensure end-user privacy and security of the data they gather.

Shift to sustainability

The course on environmental sustainability has heightened awareness among manufacturers and consumers. The concept of "environmental responsibility" impacts the decision-making process when customers embark on purchasing journeys. The integration of digitization and automation within the automotive industry, particularly in supply chain operations and shipping processes, can help reduce the negative impact of automotive production. However, manufacturers need to follow worldwide regulations that require them to make more ecologically friendly and safe vehicles. This shift requires automotive companies to embrace digital transformation at each level of their businesses.

By choosing the right investment strategy, enabling customer data privacy, restructuring business, and applying the principles of sustainability, automotive companies will successfully achieve digital transformation and reap its benefits.

Key digital transformation trends for automotive

If a company wants to remain competitive in the automotive market, they need to keep track of digital transformation trends in the automotive industry. Learn where the automotive industry moves in the present day and apply the same practices to grow your business.

Use of manufacturing robotics

The automotive sector has a longstanding history of incorporating robotics within assembly lines to enhance operational efficiency. Presently, this approach has become a trend. BMW Group is a perfect example of a company that integrated a new system, leveraging NVIDIA technologies. Their end-to-end solution includes logistics robots operating on NVIDIA's open Isaac robotics software platform. The robots can transport materials and work with vehicle components.

Virtual car tours

As for retailing automotive trends, manufacturers have started to apply immersive virtual experiences on their websites. Retailers offer virtual car tours, which enable users to check every detail of a vehicle from the convenience of their homes. This represents a significant shift in the consumer experience, providing a detailed and comprehensive exploration of cars due to the industry's transformation.

Sensor integration

The demand for sensors in the automotive industry increased, especially for those related to Advanced Driver Assistance Systems (ADAS) and autonomous driving. According to McKinsey report, the predicted market demand growth for automotive sensors is by 8 percent by 2030.

Connectivity features

Automotive manufacturers initiate the creation of new vehicles boosted with connectivity features. Customers seek for a transformative shift in their automotive experiences. This is why manufacturers connect vehicles to various applications and social media platforms, provide customization options for navigation, ensure digital support for drivers, and enable seamless parking fee payment directly from the car’s dashboard.

Using robots to take care of certain parts of the manufacturing process, enabling virtual product checks, integrating cutting-edge sensors, and integrating connectivity into the vehicles ensures that a manufacturer will attract more customers and increase their profit.

How Lemberg Solutions contributes to the digital transformation of the automotive industry

Embedded engineers at Lemberg Solutions have helped several clients to embrace digital transformation within the automotive industry. Read below to learn more about our cooperation and project development.

Android Automotive OS app development for Road.Travel

Android Automotive OS is a relatively new technology, requiring profound Android development skills. Road.Travel chose Lemberg Solutions as their tech partner since our developers had needed expertise. Besides, our engineers have a full technical understanding of implementation limitations associated with various types of AAOS distros and can adhere to strict app development guidelines from Google. We released an MVP app and met a strict deadline to address the requirements of automotive OEMs waiting for the first release.

AUTOSAR-based battery management system with advanced SoC and SoH algorithms

Our data science and embedded engineers aimed to build an advanced BMS with enhanced accuracy of SoC and SoH algorithms for hybrid electric vehicles and electric vehicles. The Lemberg Solutions team used automotive grade components and designed a system that complies with ISO 26262 standard. We took care of the following safety features: Over/Under Voltage, Over/Under Temperature Protection, Short Circuit Detection, Cell Balancing, CAN Communication, and Fault Handling.

The algorithms we’ve created use data from temperature, current, battery chemistry, and capacity sensors to enable 96–98% of SoC algorithm accuracy. The system ensures correct driving range determination, prolongs battery pack lifespan, and reduces the risk of fire incidents. Check out the development details.

Digital assistant for drivers

Our client was looking for a professional mobile app development team to help them build native iOS and Android apps for their automotive device, Chris. Chris is a voice-controlled digital assistant that helps drivers use their smartphones while staying safe on the road. In addition to app development, our developers assisted the client with back-end maintenance and support for Chris. We provided the client with team extension, back end & API, support & maintenance, iOS development, android development, and DevOps services. Read more here.

Wrapup

Presently, digital transformation has become a must in numerous industries. However, the automotive sector is one of the fastest growing and most complex to transform. Vehicle manufacturers need to change their business management practices and production processes. To stay competitive, they need to consider robotics as a part of business automation and integrate AI solutions not only in vehicles but also in manufacturing operations. Such modifications can be challenging and require competent and skillful engineers who can help automotive companies improve.

Considering digital transformation for your business? Contact our experts and get the help of professional embedded and data science engineers.