Low-power embedded design involves electronic systems that consume minimal power while still providing the necessary functionality.

Low-power devices are everywhere, from fitness trackers and smartwatches to wireless medical sensors and IoT environmental monitors. Plugged-in devices that spend most of their time in standby mode—Wi-Fi routers, printers, and home assistants—also rely on low-power design. While not battery-operated, their standby energy usage contributes significantly to overall power consumption in embedded system, especially when multiplied across millions of households and offices.

At the heart of low-power design lies a constant trade-off: how to maintain sufficient processing power and responsiveness without sacrificing performance. In applications where power is scarce or where energy waste accumulates silently in idle states, engineers must make strategic decisions about whether to prioritize speed or extended efficiency.

In this article, we’ll explore the core challenges of low-power design and share practical strategies that our engineers utilize to make smart, energy-conscious design choices.

Why is low-power embedded design important?

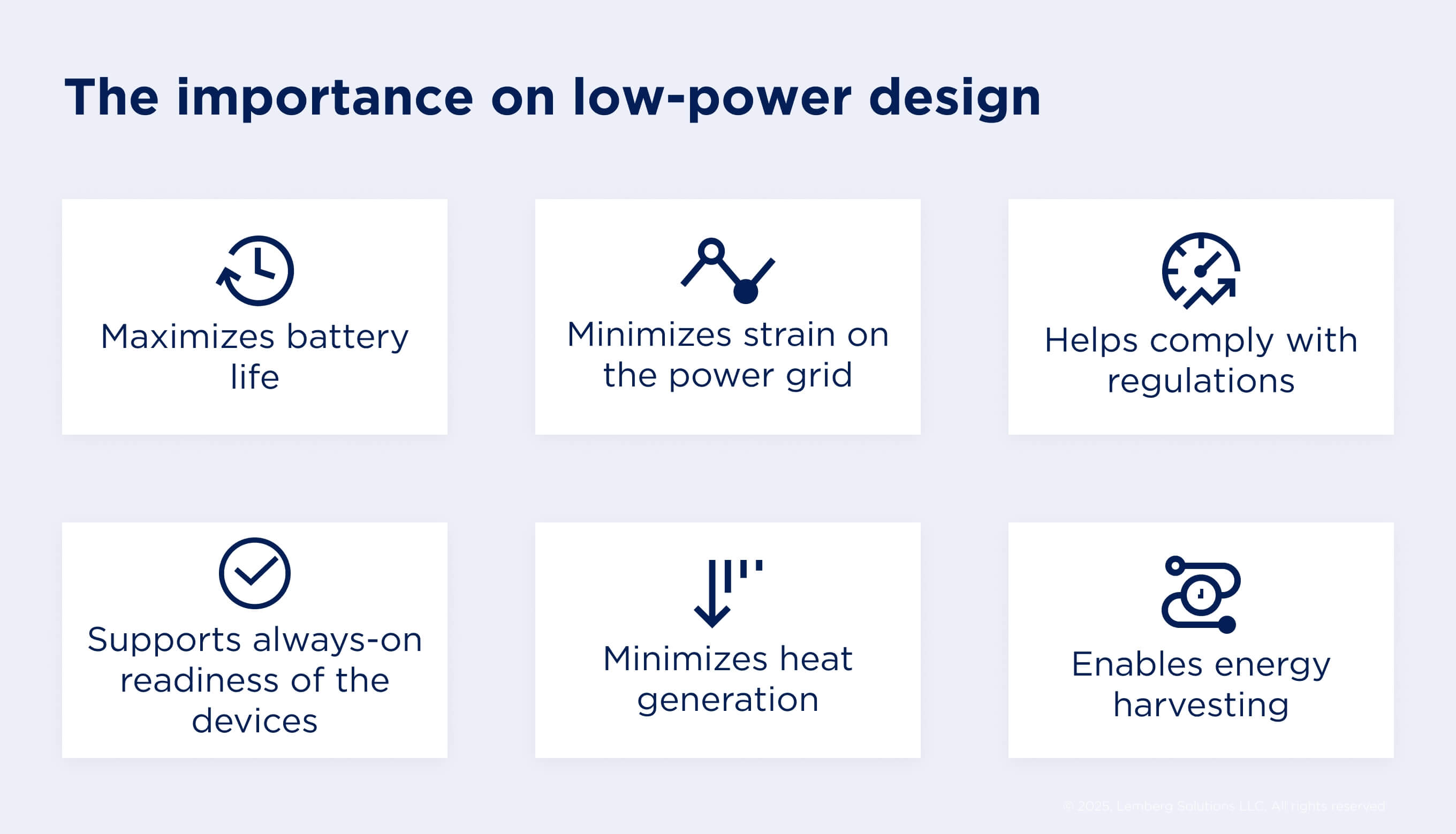

In a world driven by mobility, connectivity, and sustainability, low-power design has become a foundational requirement in modern electronics. Whether it's a battery-powered wearable, a medical implant, or a plugged-in smart device sitting idle in standby mode, minimizing energy consumption is critical. In embedded engineering, the low-power system design pursues the following goals:

- Maximising battery life. Always-on, battery-powered devices such as pacemakers, smartwatches, and other wearables often consume energy even when not actively in use. Thus, they are highly dependent on low-power management to prolong battery life and ensure reliable long-term performance. Battery longevity is especially important in healthcare wearables. Indeed, extending a single pacemaker’s lifespan from 10 to 15 years can significantly enhance patient outcomes while reducing the need for surgical replacements.

- Minimizing strain on the power grid. Low-power design is also beneficial for wired devices. The sheer number of connected devices used at homes and workplaces can lead to significant cumulative power waste (standby power). In fact, standby power accounts for 5-10% of total residential electricity consumption in Europe. In the U.S., this number is even higher, estimated to be as much as 10–15% of total annual electricity usage. While low power modes are designed to reduce energy consumption, they can still contribute to energy waste if not properly managed.

- Achieving regulatory compliance. For wired systems, proper low-power design helps meet energy-focused requirements. Notably, EU Regulation 2023/826 mandates that, as of 2025, power consumption must not exceed 0.5 watts for electronic devices in off mode and 0.8 watts for those in standby mode. The regulation affects manufacturers of consumer electronics, electric vehicles, office equipment, and smart home devices.

- Improving user experience. Properly designed low-power systems in wearable devices ensure longer battery life, reducing the need for frequent recharging and improving everyday convenience. As a result, users benefit from reliable, always-on functionality in compact, comfortable form factors.

- Optimizing energy harvesting. A well-configured low-power design reduces heat output, improving comfort and wearability. It also enables energy harvesting from sources like motion, light, or body heat, which helps extend battery life and supports sustainable, maintenance-free operation.

The importance of properly designed low-power systems cannot be overstated. For wearable devices that rely on battery power, this means a better consumer experience.

5 Steps to efficient low-power embedded design

1. Use a smart power distribution architecture to manage power across different voltage domains

Low-power systems typically rely on multiple voltage domains, with each domain supplying power to specific functional blocks such as processing cores, memory units, sensors, and wireless communication modules. Depending on factors such as clock frequency or operational mode, different internal subsystems may require distinct voltage levels. And here is a challenge: solutions that perform well under high current demands often lose efficiency when operating at low loads, leading to unnecessary energy waste.

To maintain efficiency across different operating scenarios, engineers should integrate a mix of power management components, including low-dropout regulators (LDOs), switching regulators (DC-DC converters), and smart power management ICs. These components help regulate supply levels dynamically in response to fluctuating load demands and can also support energy harvesting features when necessary.

2. Prioritize communication protocols that are optimized for low energy consumption

In ultra-low-power systems, wireless communication often accounts for a significant portion of total energy usage. Transmitting data over protocols like Bluetooth, Wi-Fi, or Zigbee generally consumes far more power than local data processing or computation. This creates a fundamental challenge in battery-powered and energy-harvesting devices, where excessive transmission time or inefficient communication strategies can quickly deplete limited energy resources and negate the advantages of low-power design.

To address this, engineers must prioritize communication protocols that are optimized for low-power energy consumption. Standards such as Bluetooth Low Energy (BLE), Zigbee, and Wi-Fi 6 are specifically designed to reduce radio-on time. Complementary techniques, such as wake-on-radio, data compression, and adaptive duty cycling, help limit both the frequency and duration of wireless activity.

3. Manage leakage current properly

Engineers must properly manage leakage current. GPIO pins are the common yet often overlooked leakage sources. In normal operation modes, the GPIO leakage current may be negligible. Yet, when the system enters a low-power or sleep mode, the microcontroller itself may consume as much as 1 μA. Thus, improperly configured GPIOs and board-level components can cause leakage currents of hundreds of microamperes.

To minimize GPIO-induced leakage, every unused pin must be properly reconfigured before entering low-power modes. The standard approach is to set unused GPIOs as analog inputs, which prevents internal pull-ups, pull-downs, or floating states that could create leakage paths. Additionally, all active peripherals must be reviewed and transitioned to their lowest power settings or completely disabled if they are not needed.

4. Support fast wake-up times and low-latency power state transitions

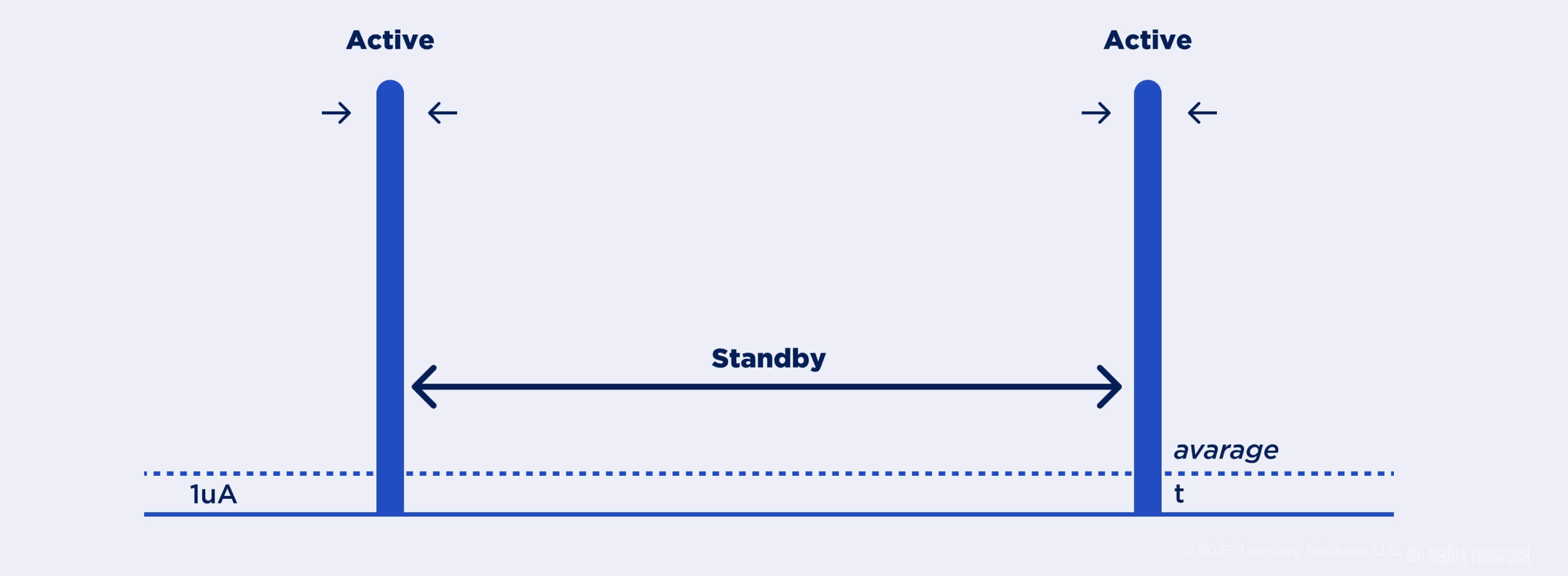

Low-power devices are often designed to alternate between active and low-power (or sleep) states to minimize overall energy consumption. While this strategy is effective for extending battery life, frequent switching between these states can introduce performance trade-offs. Each transition back to active mode can incur a cost, not just in terms of time, but also in power. For instance, when the system awakens, it may need to reload code or data into RAM, reinitialize peripheral interfaces, or wait for internal clocks and voltage regulators to stabilize. In applications where timing is critical, these delays can impair responsiveness and reduce operational efficiency.

To solve this issue, engineers must design systems that enable rapid transitions between power states. One effective approach is to incorporate retention modes, which allow the system to preserve critical memory content, register values, and configuration settings even during deep sleep. This significantly shortens wake-up times and lowers the energy required to resume full operation, since the system avoids repetitive reinitialization processes.

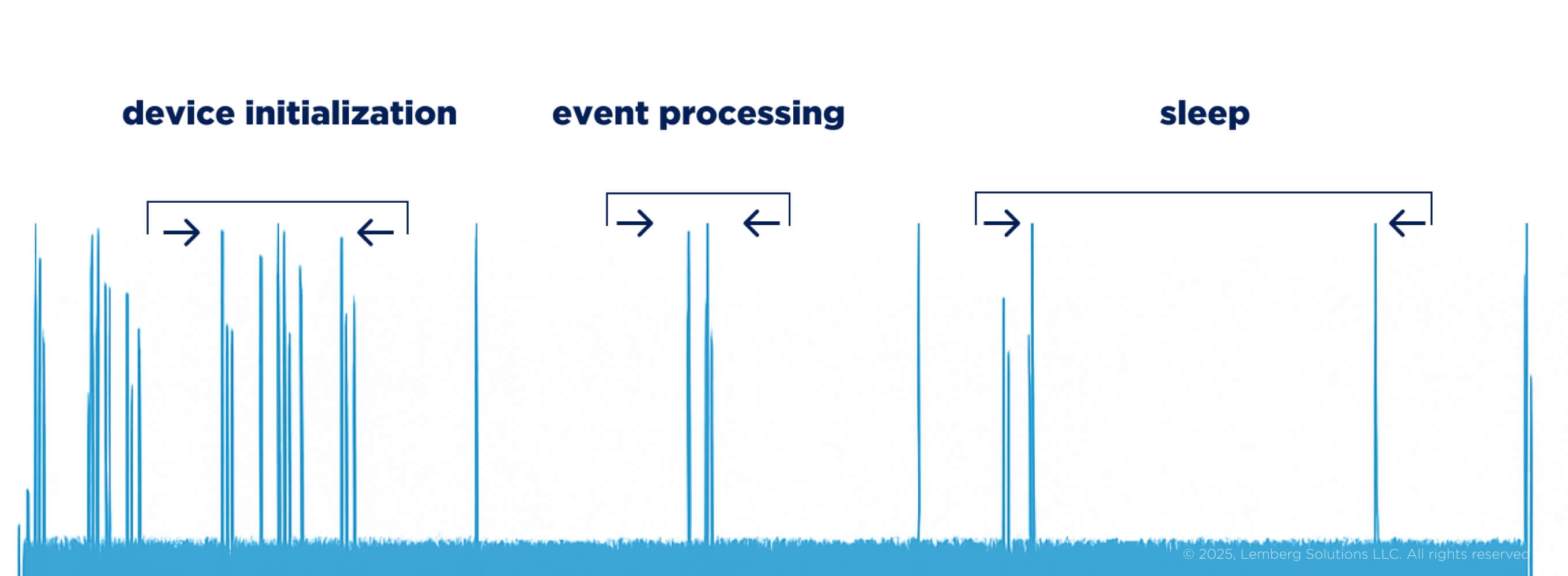

5. Conduct power measurements early in the development process

Energy-constrained applications require frequent power consumption measurements throughout the development cycle. The measurements early in the development process prevent design deviations and costly redesigns. For instance, when developing a battery-powered medical sensor that must have a defined battery longevity and operability, frequent and precise measurements are highly necessary.

Conducting power measurements early in the development process helps identify hidden inefficiencies, whether they stem from inappropriate battery selection, suboptimal software architecture, or poorly configured hardware components. Gaining this insight early can not only accelerate development but also determine the overall success of the project.

How low-power embedded systems are developed at Lemberg Solutions

Lemberg Solutions has a deep expertise in developing low-power embedded software, electronics, and auditing such systems.

Low-power embedded software for a noise monitoring device

One of the examples of our low-power embedded expertise is the improvement of a noise monitoring device for NoiseAware. The service was developed to monitor noise levels at a property and send alerts via a dashboard or mobile app.

For this case, Lemberg Solutions improved the wireless communication between TI CC1310 modules, nearly doubled the devices’ working range, and optimized battery-saving modes. Our embedded engineers configured the device’s sensors to switch intelligently between long-range high-power and short-range low-power modes. To further reduce power consumption of an embedded system, we introduced four dynamic configuration profiles tailored to various operating ranges. LS engineers developed a state machine that allows the noise monitoring devices to alternate between work modes. We implemented the tethering protocol as one of the states and added a listener code, enabling the indoor sensor to collect information from multiple outdoor sensors simultaneously.

A custom state machine allowed seamless transitions between work modes, while listener code enabled indoor units to gather data from multiple outdoor sensors. A tethering/MAC dispatcher was added to regulate communication load, and detailed analyses of memory, processing power, and battery usage provided actionable insights for future feature development.

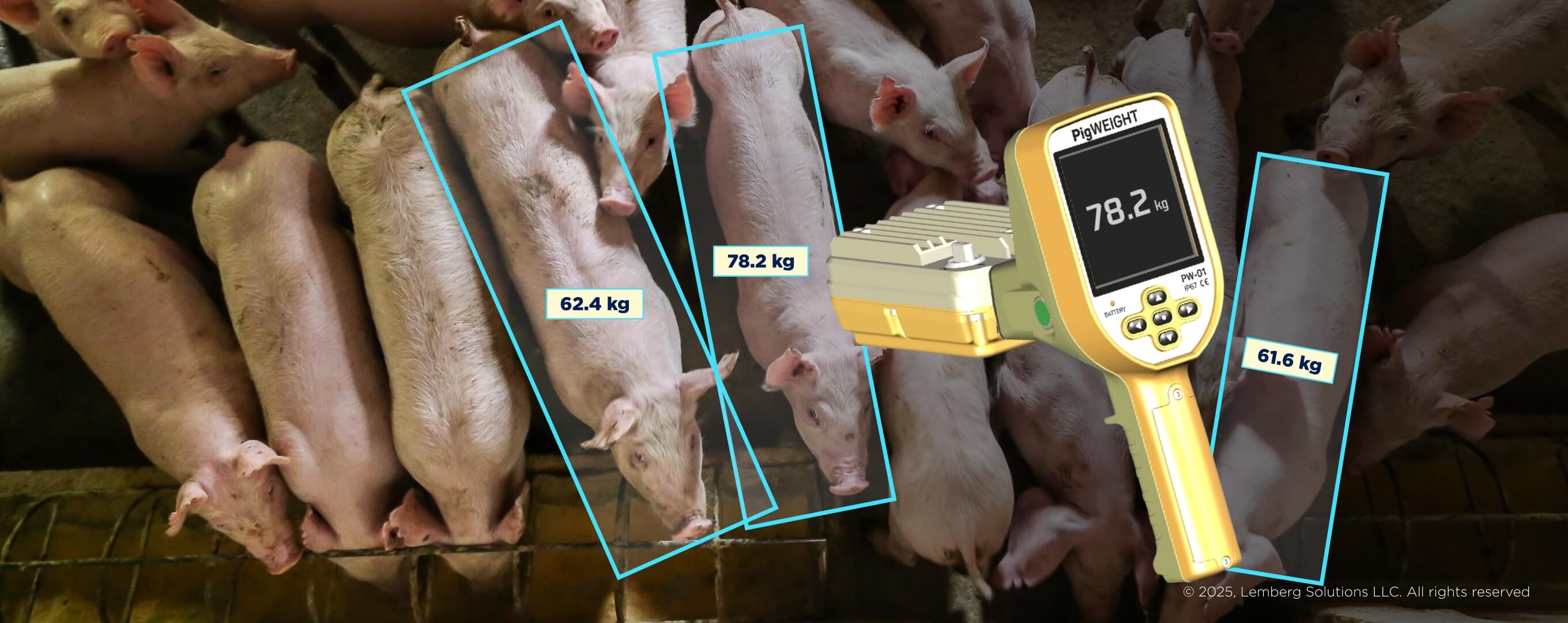

Low-power embedded electronics for a wearable livestock monitoring device

Low-power embedded electronics are transforming livestock farming by enabling smart, autonomous solutions with minimal energy consumption. For Barkom Ltd., Lemberg Solutions engineered a custom low-power device to automate pig weight monitoring while maintaining long-term reliability in farm conditions.

Our team developed optimized embedded software and selected energy-efficient electronic components to ensure extended device operability on limited power sources. By carefully balancing processing performance with power constraints, we delivered a compact, intelligent system capable of collecting and processing data in real-time, without requiring frequent recharging or maintenance. This project demonstrates how low-power embedded technologies can unlock scalable automation in energy-sensitive environments.

Read more about five real-life examples of embedded system design.

Key takeaways

Crafting low-power embedded systems is all about making informed compromises. Engineers must carefully navigate performance constraints, energy consumption, leakage currents, power states, and communication overhead to achieve a desired result. It’s a demanding process that calls for both deep technical knowledge and innovative thinking. But the payoff is creating intelligent devices that can operate for years on minimal power.

Don’t want to be involved in power-performance trade-offs in your devices? Consider embedded software outsourcing. Our engineers can help solve this and other challenges in your low-power systems, so you can focus on functionality, speed up development, and bring energy-efficient embedded systems to market with confidence.

FAQs

What is a low-power embedded system?

A low-power embedded system is a device designed to perform specific tasks while consuming minimal energy. These systems are often battery-powered or rely on energy harvesting and are optimized for sleep modes, efficient processing, and minimal leakage current. They’re commonly used in wearables, medical devices, smart sensors, and remote IoT applications.

How do you select the microcontroller brand/part for your low-power embedded design?

Selection depends on the application's power budget, performance needs, and peripheral requirements. Engineers review datasheets for active and standby currents, sleep modes, and wake-up latencies, and consider vendors such as TI, STMicroelectronics, Nordic, or Microchip based on the project's fit.

What are the benefits of using low-power electronic devices rather than high-power ones when designing an embedded system?

Low-power devices extend battery life, reduce heat generation, and enable longer operation in remote or wearable systems.