Embedded software development for 3D bioprinters

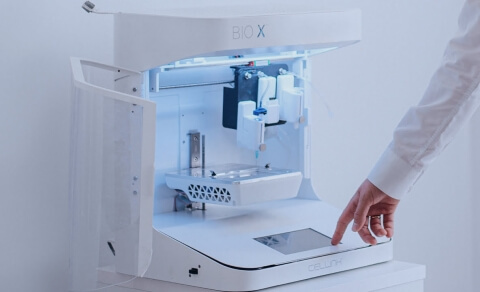

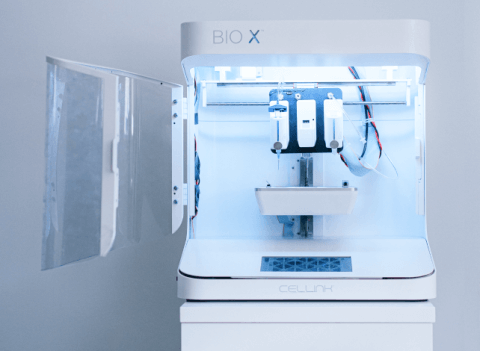

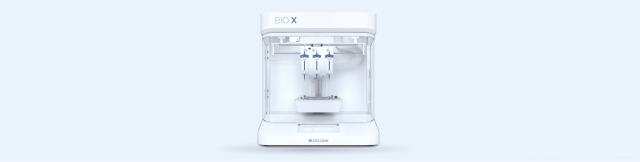

CELLINK (part of BICO) is a Swedish bioconvergence startup that is a leading innovator in the development of bioprinters and biomaterials. Combining biology, engineering, and computer science, CELLINK is furthering the evolution of technologies for creating bioprinted human organs and tissues.

The challenge

Scaling their business at a brisk pace, CELLINK wanted to find a reliable tech partner with solid experience in the development of IoT systems who could provide experts in С++, Qt, Embedded Linux, Marlin, MQTT, and Flutter. With bioprinters already in production, CELLINK was searching for a dedicated team able to maintain their code through bug fixing and polishing to make their bioprinter devices function even better.

Delivered value

Lemberg Solutions was able to quickly set up an initial team of Embedded Linux/Qt engineers and later scale it based on actual business needs. Our client was happy to have us quickly onboarded and ready to improve their Qt and Embedded Linux apps as well as a customer web portal built on Flutter. Aside from fixing bugs and refactoring code, we contribute to developing new features allowing for more convenient 3D modeling of human organs.

The process

CELLINK had already been working with distributed teams when they contacted Lemberg Solutions. They were looking for a tech company providing embedded Linux development services and relevant specialists to add even more skills to their team. Lemberg Solutions engineers have extensive expertise in IoT system development and, after several interview rounds, CELLINK was convinced of our professionalism and decided to start cooperating with us.

To manage their remote workers, CELLINK sticks to a Scrum workflow and holds regular meetings. Also, they ensure close communication between remote teams around the globe to integrate improvements as fast as possible.

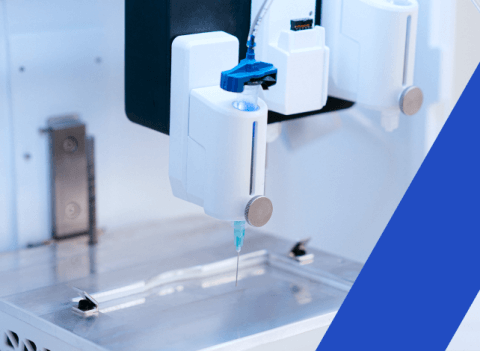

The client’s main request was to establish continuous improvement of their Qt apps, middleware, and firmware. CELLINK sent us their BIO X printer right away so that our Qt engineers could effectively integrate the changes and check all new features locally before releasing them to production. Since different printers have different configurations, we use printer-specific app development approaches. For the BIO X printer model, which has an embedded UI, our engineers apply QML, while the BIO X6 requires using Qt Widgets.

To make the devices function more smoothly, LS engineers modified the Embedded Linux apps, developing new features for them. Along with that, we fixed communication errors between the UI and the printer’s middleware. Since the client’s code is similar to Marlin, our engineers leveraged their knowledge of this software framework that runs on most 3D printers.

To provide their clients with constant support, CELLINK created a customer portal running on Flutter Web. Our Flutter engineer helped to connect the front-end of the Z-stack files page to the back-end of another product, CELLCYTE X, an automated imaging platform. This allows users to securely monitor images taken by CELLCYTE X. On top of that, our engineer debugged specific parts of the code, including the one responsible for showing release dates.

Lemberg Solutions and CELLINK are keeping the wheels of collaboration turning. We are happy to be a part of the bioprinting future and hope to deliver even more support as our cooperation with CELLINK evolves.

How it works