For years, global supply chains and outsourcing services have been an essential part of American businesses. This model allowed companies to access a wide range of expertise, components, and talent at attractive prices that they could not achieve locally.

But now the situation is changing, and the U.S. at the national level is moving toward complete sovereignty — economic, political, military, and technological. This forces U.S. businesses to focus on protecting their products, operations, and supply chains from present and unpredictable future risks.

Localization, protectionism, and outsourcing anxiety

Outsourcing has become a major concern.

“According to insights from CES 2026, 80% of СЕОs consider having an offshore vendor a strategic threat and aim to reduce such dependencies by 2030.”

And major American market players have already been moving toward sovereignty and localization.

For example, Apple announced to invest more than $500 billion in the U.S. over the next four years to expand local production. They plan to open a new manufacturing facility in Houston, create an academy for the next generation of U.S. manufacturers in Michigan, and expand their R&D centers locally. Similarly, General Motors has instructed thousands of suppliers to prioritize vehicle components from North American factories.

At the federal level, lawmakers are also taking initial steps to reinforce this trend. For example, in September 2025, the Halting International Relocation of Employment (HIRE) Act was introduced in the Senate. Under this proposal, all payments by American companies to foreign countries for services will be subject to a 25% tax. This approach aims to make outsourcing more expensive, so companies would opt for hiring local talent. As of early February 2026, the act has not been enacted.

Current shifts in foreign policy, evolving regulations, and the growing use of sanctions leave local businesses facing a critical question: how to adapt to a new reality and navigate constraints, while preserving both control and competitiveness.

The limits of sovereignty

Replacing dependence on the global supply chain demands domestic independence. But the catch is that a considerable shortage of both human and material resources can make such a transition challenging.

The supply chain

Despite active efforts to support local production, U.S. manufacturers remain deeply tied to global supply chains. Almost all critical components and rare materials are produced and sourced from outside the United States.

Among the most import-dependent sectors are the critical ones — defence, energy, healthcare, and transportation. For example, around 81% of the U.S. defense product value chains come from foreign inputs. And while the American administration is trying to promote domestic production, some components cannot be sourced domestically at all. The United States is 100% import-dependent for materials such as gallium, graphite, rare-earth elements, fluorspar, etc.

This reliance goes beyond just raw materials. Currently, the U.S. does not have the domestic capacity to produce many advanced components, like high-performance rare-earth permanent magnets. While metals needed for the product are available locally, finished products have to be imported from other countries.

These dependencies create vulnerabilities across many sectors and pose risks to future technological advancements.

Upcoming energy emergency

Much of modern infrastructure and manufacturing consumes significant amounts of energy, and the country’s grid capacity does not provide enough energy for everyone.

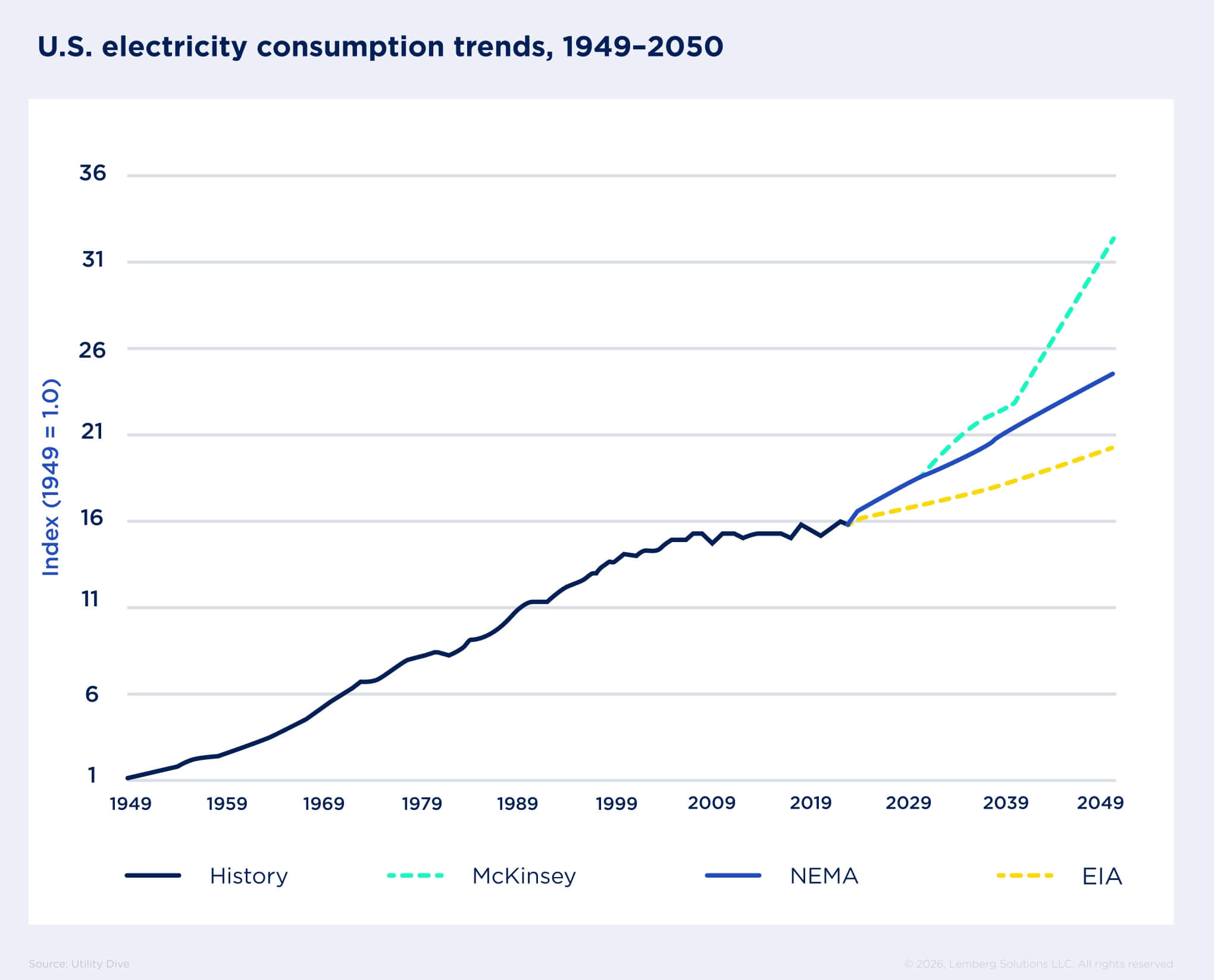

“The electricity demand of the United States is expected to grow 15–20% over the next decade and potentially double by 2050, as a result of transport electrification, AI computing, and advanced manufacturing.” (Stanford News)

The current system, consisting of six regional grids with limited interconnection, is not designed for the high‑intensity loads required by modern manufacturing. Also, the rising energy costs make fully domestic production economically unsustainable. In 2025, energy costs increased by 11% and are expected to rise, especially due to demand from data centers, Bitcoin mining, electric vehicles, and extreme weather conditions.

At the same time, the administration has paused the development of renewable energy solutions, such as wind power projects, which are among the cheapest domestic sources of electricity. To address high energy prices and rising demand, the U.S. government launched a series of strategic actions to boost domestic fossil fuel production.

Labor shortages

The American labor market is now experiencing a shortage of skilled workers ready for physically demanding roles.

By May 2024, there were more job openings than unemployed people in the U.S. It is about 1.5 million more jobs than workers looking for them. By February 2025, 4.5% of all jobs were still unfilled. (McKinsey)

Fewer people are entering the local workforce, despite businesses' efforts to attract them. Without enough qualified specialists, projects can slow down, costs rise, and strategic goals can become difficult to execute. The pressure is especially evident in construction, healthcare, and the food sector.

At the same time, minimization of offshoring cooperation might intensify competition for a limited pool of domestic talent and skilled engineers. There is a risk that only large, well-established businesses will be able to win the local hiring process. For smaller and mid-sized businesses, competing might be difficult, as they cannot invest much in in-house employees and offer higher salaries or maintain a proper recruitment process.

Practical strategies for operating under uncertainty

If you are at a crossroads and wondering what to do next, these strategies can help you adapt and make your business more resilient.

#1 Diversify suppliers and design

Diversification of suppliers is not a brand-new strategy. Some of the largest U.S. business giants have been through this process for a long time. For example, until 2018, China and South Korea were Apple's main suppliers of batteries and their components. Now, the situation has changed: they source components from five different suppliers.

But what is more crucial is not only where suppliers are located but also how products are designed. Now, all modern architectures must be built modularly, meaning the design is divided into smaller individual modules. This allows businesses to easily accommodate alternative components from other suppliers without redesigning the entire system. Also, different modules can be manufactured or sourced in parallel, which shortens production time and simplifies inventory management.

“Modular product design is a sustainable approach, but it has its challenges. Successful implementation depends on carefully aligned modules to ensure full compatibility. For this, companies should find professionals who understand how to manage complex systems and standardize interfaces” (Pavlo Matiieshyn, Head of Embedded Engineering)

Once businesses address this, modular product design helps to reduce reliance on a single supplier and minimize the risk of geopolitical restrictions that might affect their cooperation.

#2 Risk mapping and resilient outsourcing

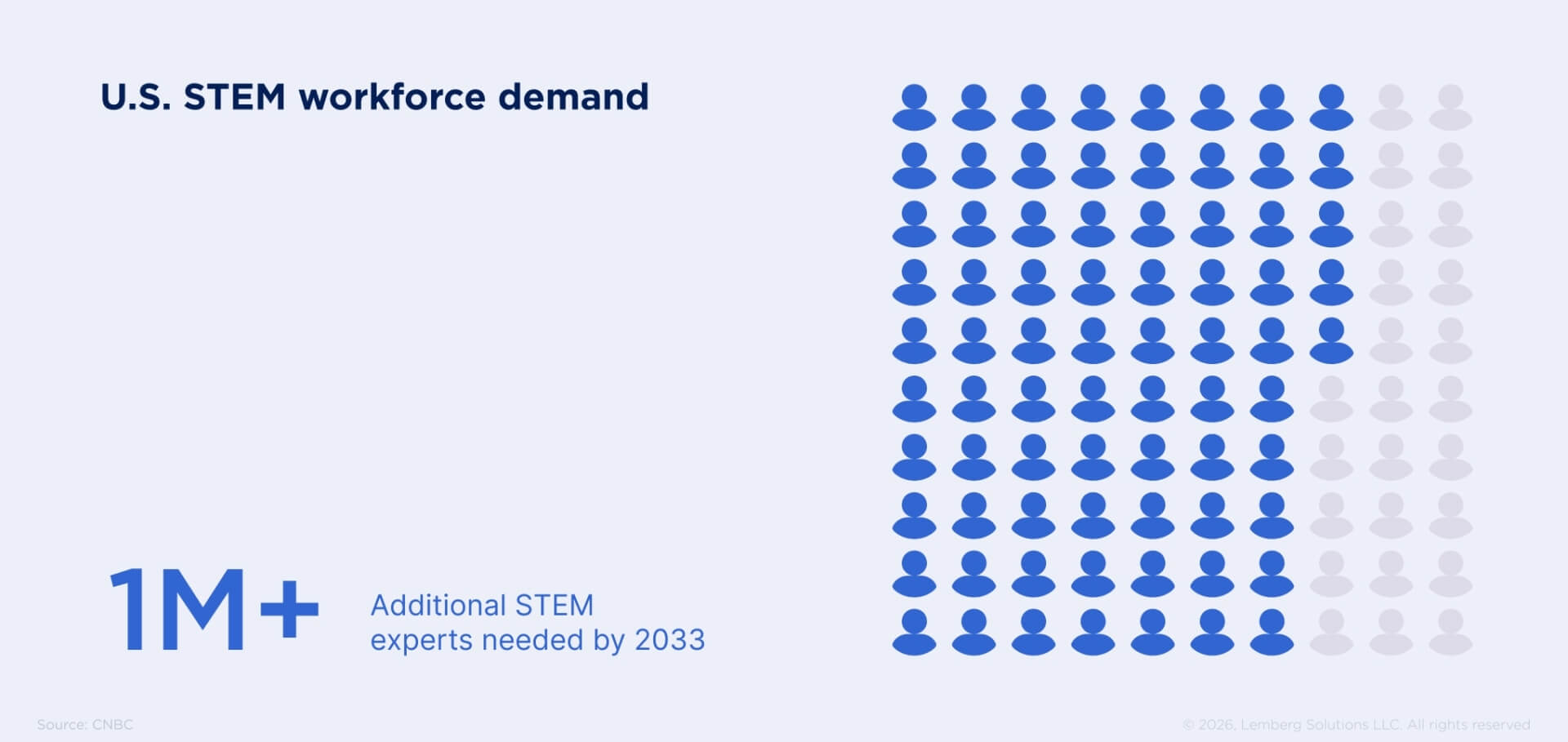

Meeting all technological needs locally is often a financially challenging and unrealistic task. According to the Bureau of Labor Statistics, the United States is to demand around 1 million extra STEM experts between 2023 and 2033.

An effective way to address this gap is to outsource to professionals in other countries.

However, the value of offshore outsourcing goes beyond simple cost efficiency. It offers many more benefits — the ability to innovate more quickly; the flexibility to scale the offshore vendor team up or down without legal penalties from employee protection laws; and the ability to maintain round-the-clock operations.

All of these benefits cannot be replicated with an in-house team. However, recent geopolitical disruptions demand a completely new approach to offshoring to avoid loss of intellectual property or access to critical components. The key lies in anticipating risks and preparing both internally and with service suppliers.

A major trend is that traditional offshoring vendors are now transforming into strategic partners. This approach completely restructures the relationship between teams.

“Clients are seeking service providers who do more than just execute (KPMG).”

Instead, they must share the responsibility for the product and operations and think alongside in-house teams to solve strategic issues. Such partnerships also require flexible delivery models that can adapt as business needs and external conditions evolve.

For example, Cisco developed risk maps to assess and predict different scenarios, working directly with manufacturing and suppliers. Together, they evaluate risk factors, from a natural disaster at the site to political sanctions, and create backup plans for business continuity and cooperation.

We see this trend emerging among our clients, says Andrew Mospan, Account Executive at Lemberg Solutions. And, as an outsourcing partner and development services provider, Lemberg Solutions follows certain principles designed to safeguard our clients and their products,

We provide full intellectual property transfer to guarantee that clients own and control the product. If our client's IP rights are locked with their previous service provider, we can work to restore the source code and other important files.

During development, we focus on in-depth documentation. By writing tech guides and explanations, we ensure the client team understands how the product and its components function.

“In the event of external factors, our client can continue working on the existing product, sharing documentation and the knowledge base with a local or in-house team without starting anew.” (Andrew Mospan, Account Executive)

Now, clients value the flexibility of the vendor to work with various hardware components suppliers and manufacturers. Lemberg Solutions is a partner of STMicroelectronics, Microchip, and AWS and is actively expanding its partner network. The team implements compliant, high-quality alternatives and can perform product retrofitting to replace components that are currently prohibited without disrupting the product's functionality.

#3 Energy optimization at the company level

The upcoming energy emergency state demands deeper national-level restructuring and modernization. However, businesses can now act proactively locally within their manufacturing centers by implementing energy-efficiency strategies and using renewable energy sources.

As a first step, they should assess their processes to identify the most energy-intensive ones. Once identified, companies should consider implementing custom technical solutions for remote monitoring, prediction, and response to energy demand.

At Lemberg Solutions, we have experience developing smart energy management systems and IoT solutions for automated monitoring and process optimization. To manage power consumption more effectively, we recommend investing more in data collection and building intelligent AI systems.

“When applied correctly, machine learning and AI algorithms can predict peak loads, identify inefficiencies, and suggest real-time adjustments. These technologies are not something new, but they are an absolute necessity for businesses to reduce energy costs, mitigate operational risk, and ensure long-term energy resilience.”

#4 Physical AI – future of labor

According to analysis by the McKinsey Global Institute, recent advances in generative AI, combined with robotics, could automate up to 30 percent of current work time by 2030.

Its productivity impact is expected to be significant on a macroeconomic level. Robotics empowered by AI is not the same clumsy robots they were years ago, with a poor sense of surroundings and a limited number of movements. Now, they are already demonstrating their ability to perform some human activities completely flawlessly: cooking, moving heavy objects, and operating machinery. These autonomous systems can help reduce the labor shortage, especially in manufacturing centers.

For companies that want to increase productivity without expanding their staff, physical AI stands out as an attractive solution. However, scaling these systems requires more than just hardware, but high-quality data — properly collected, labelled, and processed. Without solid data science expertise, automation remains costly, inefficient, and difficult to scale.

Only a few businesses can rely entirely on domestic capabilities without sacrificing speed, innovation, or competitiveness.

“The current tendency toward outsourcing reflects a cautious response to political uncertainty. Businesses are reacting to geopolitical volatility, sanctions, and regulatory unpredictability, which makes long-term dependency feel dangerous for them.”

Protecting products and operations means diversifying risks and restructuring existing business models to strengthen control mechanisms. And working with reliable partners and retaining ownership of critical assets can help maintain flexibility, instead of being caught off guard by potential disruptions.