In the automotive industry, the price of a mistake is too high to risk. A car with faulty brakes can lead to fatal accidents and ruin the manufacturer's business reputation. Even minor issues affecting large volumes of produced vehicles result in massive recalls and financial losses. That's why automotive manufacturers must follow the ISO 26262 functional safety standard and ASPICE.

This article draws a line between ASPICE and ISO 26262, explaining why you need both while working on software for automotive. As an ISO 26262-compliant company, Lemberg Solutions follows these quality and safety requirements at each stage of the engineering process. Learn more about it below.

What is ASPICE?

Automotive Spice (ASPICE or Automotive Software Process Improvement and Capability Determination) is a standard (or framework) used to improve and assess the capability level of automotive software development processes of OEM suppliers. It provides software engineers and adopters with a framework and best practices to effectively build reliable, high-quality solutions. The main point of ASPICE is continuous software development process improvement for detecting all real and potential problems as early as possible during product development and making all processes more efficient.

What are the benefits of ASPICE?

ASPICE compliance means meeting automotive software development guidelines that help avoid mistakes at the final development and manufacturing stages. According to estimates, ASPICE adoption decreases bugs by 30% and reduces maintenance effort by 28% while increasing development costs by 9% only.

To be more precise, by following Automotive SPICE software quality practices, you can:

- Improve quality. ASPICE defines rules for gathering qualified input, which helps create products that meet initial requirements.

- Reduce expenses. As rigorous testing allows you to detect flaws early on, you are more likely to do everything right from the beginning. It means less re-work, increased productivity, and optimized expenses.

- Manage risks. Automotive SPICE gives you more control over development quality to prevent unexpected bugs.

- Meet customer requirements. Since requirement analysis is crucial for compliance, you understand customer needs better and ensure meeting them at each stage of development.

- Optimize software development. This standard aims to make automotive software development more streamlined and organized. That's why adopting it improves engineering team performance.

How ASPICE affects automotive development

There are two main things to understand about ASPICE: core processes and compliance levels. Let's briefly talk about each.

ASPICE processes overview

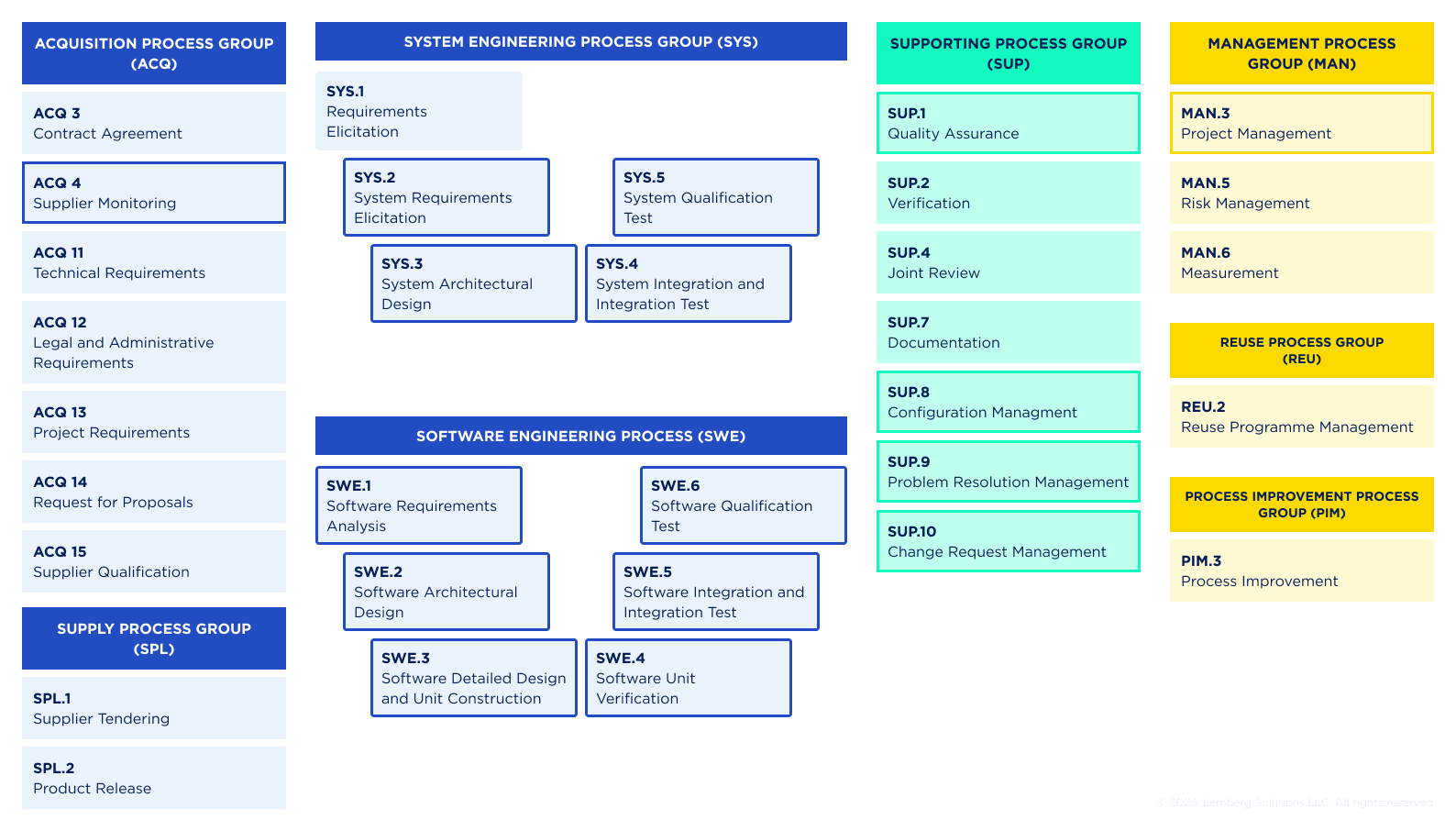

The Automotive SPICE standard includes some recommended processes organized into four categories. Each category covers a specific software development area.

- Management: Project management, planning, and quality assurance.

- Engineering: Software requirements development, design, implementation, and testing on all V-model levels.

- Support: Infrastructure and tools for the software development process.

- Organizational: Software development management, including process enhancement, training, and assessment.

ASPICE splits the development process into a V-model, which project teams should follow to create software with proper product quality. The main idea of V-model design is to increase software quality by ensuring testing at each developing stage (or developing layer). The left side of the V-model shows developing processes at each stage. The left side of the V-model shows the testing process at each stage.

A team that aims to follow ASPICE in their SDLC must perform the next sequence of designing stages: System Requirements Analysis, System Architectural Design, Software Requirements Analysis, Software Architectural Design, Software Detailed Design, and Unit Construction while running tests at each step, and includes related Software Unit Verification tests, System Qualification, and System Integration tests.

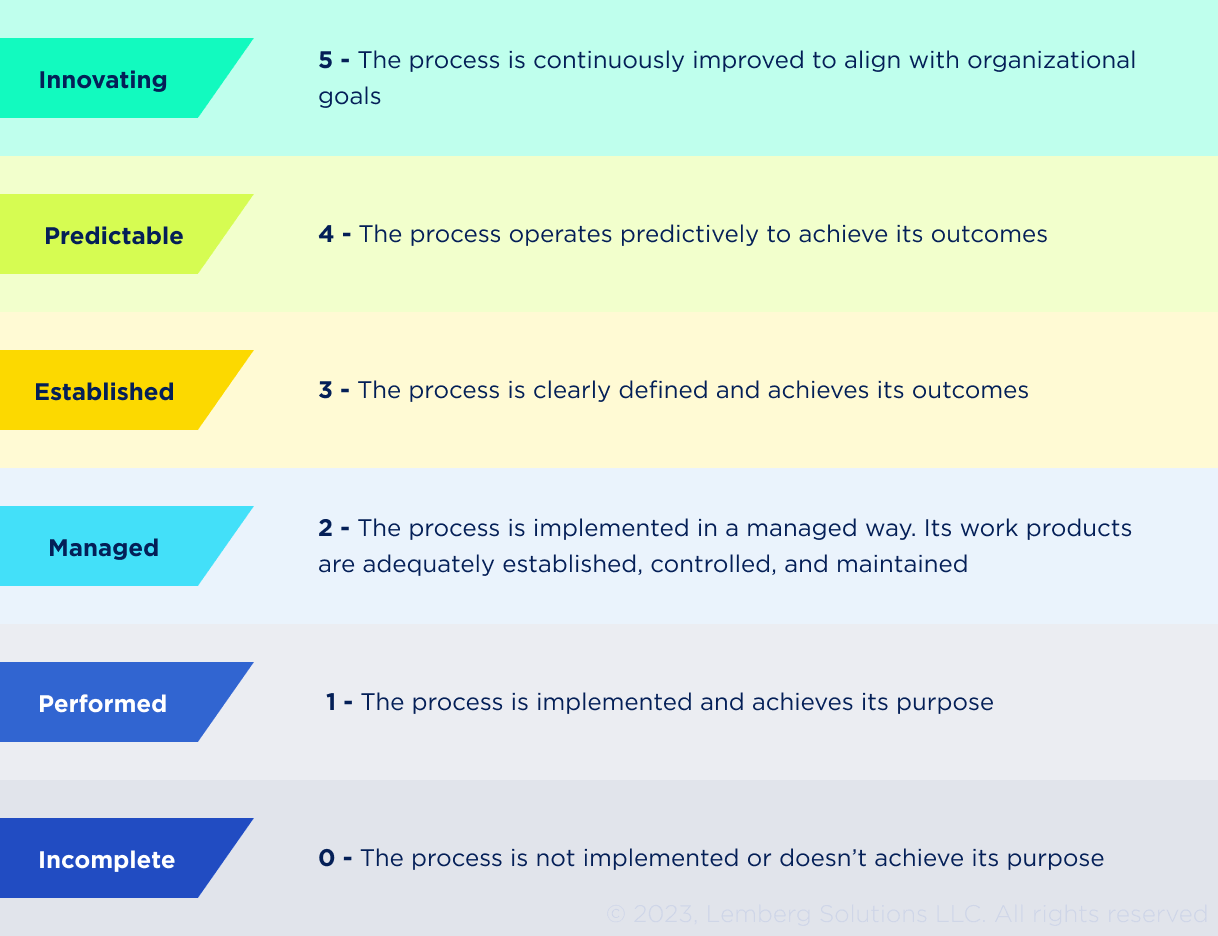

ASPICE capability levels and software development

ASPICE compliance generally has five levels, ranging from non-compliance to innovation. While looking for an automotive software development partner, you need someone with at least the second process capability level. The second level of compliance means a company appropriately manages the development process and can ensure product quality. Reaching the third level is already a considerable challenge, and few companies can handle it.

What is ISO 26262?

ISO 26262 safety standard applies to electronic and/or electric systems in vehicles, covering systems like vehicle dynamics control, driver assistance, and propulsion. The main goal is to reduce potential hazards for passengers using E/E in-car solutions.

Automotive functional safety ISO 26262 regulates the entire development process, from requirements specification to implementation, validation, and configuration.

What are the benefits of ISO 26262?

First and foremost, the functional safety standard allows car manufacturers, their supplier and design engineers to make automotive systems design, development, and production safe and reliable.

To be more precise, functional safety ISO 26262 allows you to:

- Identify potential hazards. The standard provides an efficient approach for identifying potential hazards and assessing their impact on the system. It helps engineers to develop safety requirements according to the specific needs of an E/E system.

- Increase vehicle security. Compliance is the best way to reduce the risk of injury or death caused by functional failures.

- Boost company reputation. Since safety is crucial for anyone purchasing a vehicle, consumers will appreciate compliance with the core automotive standard.

- Prevent recalls and liability claims. By manufacturing E/E in-car solutions according to industry standards, you create products with a low risk of failure.

- Stay competitive. As all leading automotive manufacturers meet functional safety requirements, compliance is mandatory to compete in the market.

- Get more control over software engineering. Meticulous planning and testing across the SDLC make automotive software development more organized.

How ISO 26262 affects automotive development

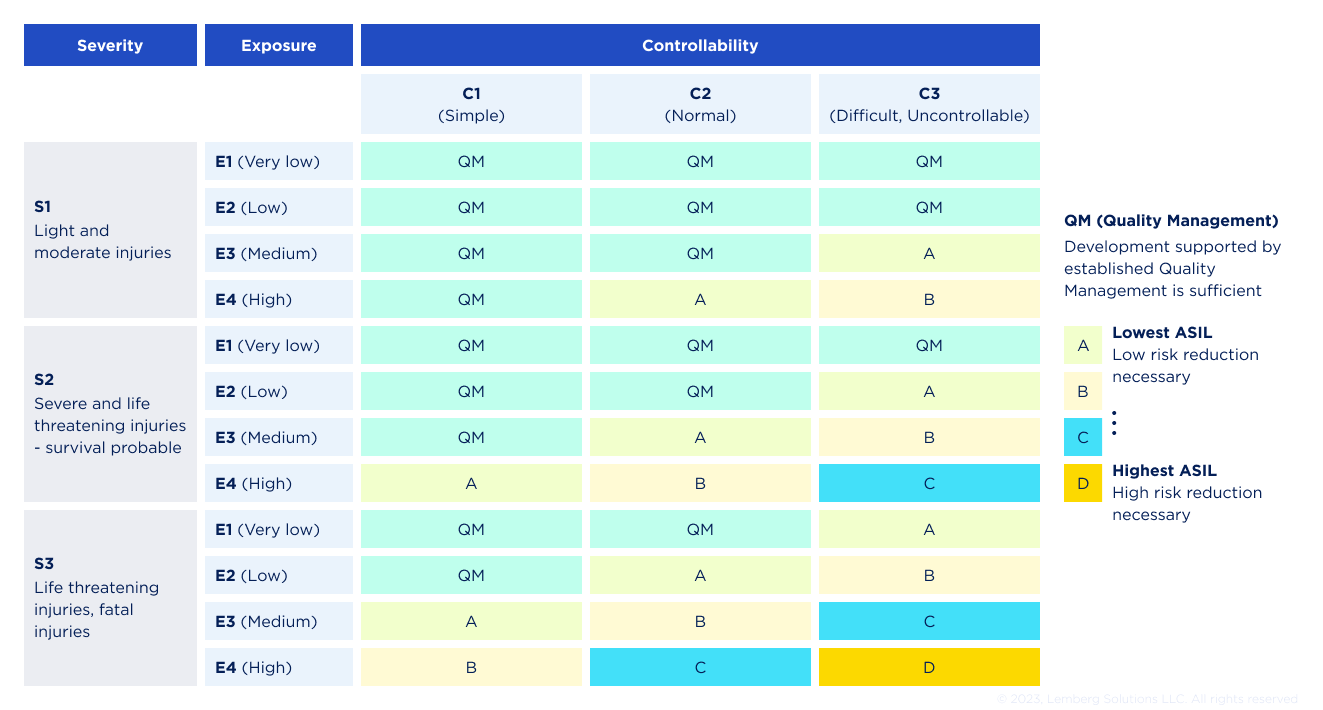

Automotive standards ISO 26262 specifies how to assign an acceptable risk level to a component or system and document testing procedures. The risk classes are called ASILs (Automotive Safety Integrity Levels) and indicate the necessary safety requirements to ensure an acceptable residual risk. An ISO-certified engineer is aware of ASIL levels and, therefore, can create a compliant device.

ISO 26262 defines four ASIL values, ASIL A, ASIL B, ASIL C, and ASIL D, applicable to hardware and software automotive design processes. ASIL D means the highest degree of automotive hazard, while ASIL A is the lowest risk. The QM level stands for hazards that do not result in any safety requirements and does not require a special design process according to ASIL levels.

The safety levels are determined based on:

- Severity (S). Seriousness/intensity of damage or consequences to passengers/road users' lives or property caused by safety goal infringement.

- Exposure (E). Possibilities of hazardous or risky situations for people in a vehicle

- Controllability (C). The extent to which the driver controls the vehicle when any automotive component fails.

For example, the combination of S2, C1, and E4 means ASIL A severity class, and the engineering team must run low risk reduction processes according to ASIL A.

ASPICE vs. ISO 26262: What is the difference?

ASPICE vs ISO 26262 is a common comparison since both are used in automotive manufacturing. Yet they have a different purpose. While ISO 26262 aims to reduce the safety risks for vehicle system end-users, ASPICE focuses on product quality from the technical requirements point of view..

Hence, while ISO 26262 is more about creating a safe product, ASPICE ensures the implementation of proper engineering practices for product quality.

Automotive SPICE/ISO 26262 integrated engineering process

ISO 26262 vs ASPICE — these two standards go hand in hand in most automotive software development projects. They both are frameworks we combine and mix to achieve different purposes throughout the software development lifecycle.

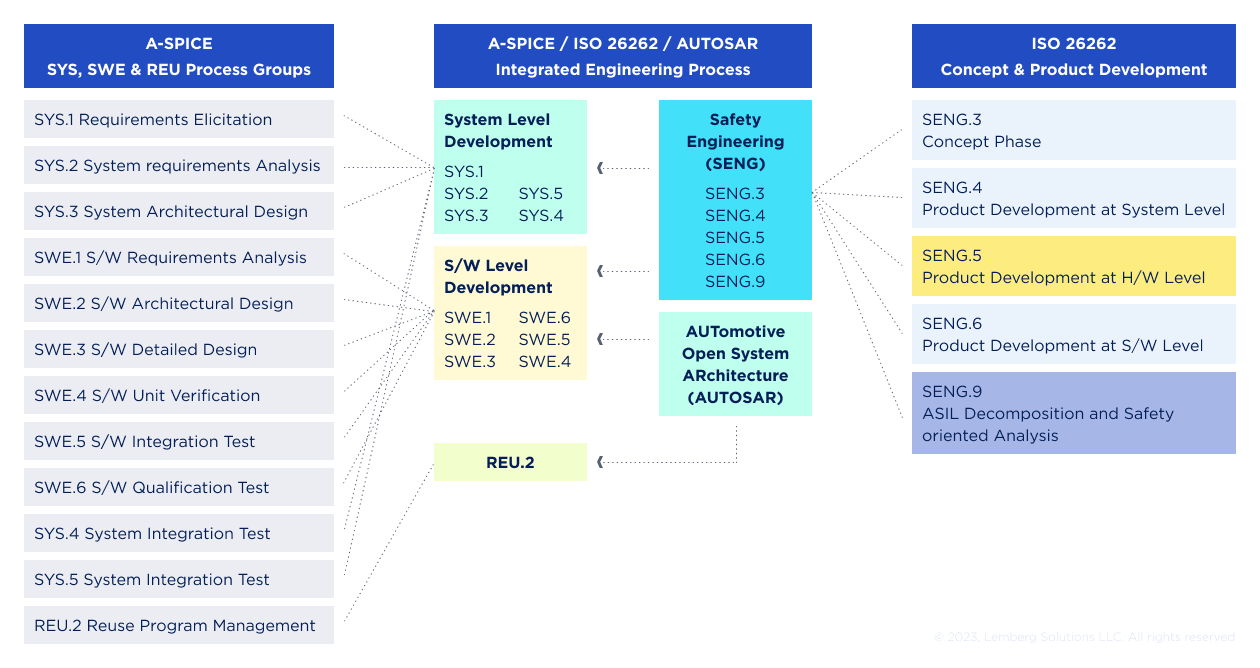

The ASPICE/functional safety combination in our company usually looks as follows:

ISO 26262 includes things ASPICE doesn't cover, like failure mode effect analysis, failure tree analysis, hazard analysis, or risk analysis. Nevertheless, they largely overlap as many mandated lifecycle processes happen simultaneously.

Benefits of working with LS as a certified development team

If you want to complete an automotive project according to ASPICE or/and ISO 26262-compliant engineering process, Lemberg Solutions can help. We are ready to assessment of the processes of our company even to capability level 3 according to ASPICE standards.

We hire ISO 26262 functional safety engineers who know how to gather requirements, organize software development, complete testing, and validate the result to create compliant solutions. The software for OEMs and Tier 1 suppliers we develop ensures the ultimate safety for end-users and peace of mind for our customers.

Tell us about your project to get help from certified automotive engineers.

FAQs

Is ISO 26262 mandatory?

No, this functional safety standard is not mandatory. Yet since it impacts functional safety, all trusted OEM and automotive software providers follow its practices. ISO 26262 is a widely used standard that provides clear guidelines for functional safety in the automotive industry.

Who must follow ISO 26262 and ASPICE?

Everyone contributing to road vehicle development should follow these guidelines, from a software engineering company to a Tier 1 supplier. Even though these standards are not mandatory, they are generally required.

How to check ASPICE compliance?

You need to order an expert audit to ensure a software engineering company follows ASPICE rules. The audit is conducted by an independent ASPICE-certified Competent Assessor from an external organization.