Human error remains one of the most significant sources of financial and reputational loss across different industries. And logistics is not an exception. Every wrong label, misplaced pallet, or delayed shipment costs more than money. It costs reputation and customer trust. But with computer vision, logistics is evolving into more intelligent environments where mistakes are detected before they occur.

Continue reading to see how computer vision is reshaping warehouse and logistics operations.

Why human error remains one of the biggest challenges in logistics

Working under time pressure, fatigue, or without proper oversight sooner or later leads to mistakes. Mispicking, inventory inaccuracy, labeling and scanning mistakes, loading and routing errors, and distracted driving are just a few examples. In practice, distribution centers lose above half a million dollars annually due to mis-picks alone. In addition, human error keeps warehouse inventory accuracy at 67–91%, meaning up to one in ten items is still miscounted or misplaced. Every percentage point of inaccuracy cascades into higher operational costs, lost sales opportunities, and customer trust.

Traditional safeguards, such as manual double-checks or additional staff, may seem like a solution. Yet, they aren’t. Especially when your business scales and the orders grow. Manual processes then become bottlenecks: throughput slows, labor costs rise, and errors still slip through because people become tired, distracted, or rushed. The reality is that manual quality control simply cannot deliver the accuracy modern logistics requires, and the financial consequences are too high to ignore.

That’s why more and more businesses are turning to automated solutions such as AI-powered computer vision (CV). It takes over the most error-prone tasks in logistics, providing real-time accuracy that manual processes cannot achieve. By reducing mis-picks, delays, and rework, it cuts costs and allows operations to scale without adding labor.

How computer vision helps eliminate human error across the supply chain

Computer vision development combines high-resolution cameras and AI algorithms to analyze logistics operations in real time. Cameras continuously capture imagery across key zones — shelves, conveyors, and loading docks. AI models then process those visual feeds to detect objects (packages, pallets, boxes), read labels or barcodes, track objects and movement, and flag anomalies (e.g. missing items, damaged goods). To synchronize inventory updates automatically, computer vision solutions integrate with warehouse management systems (WMS).

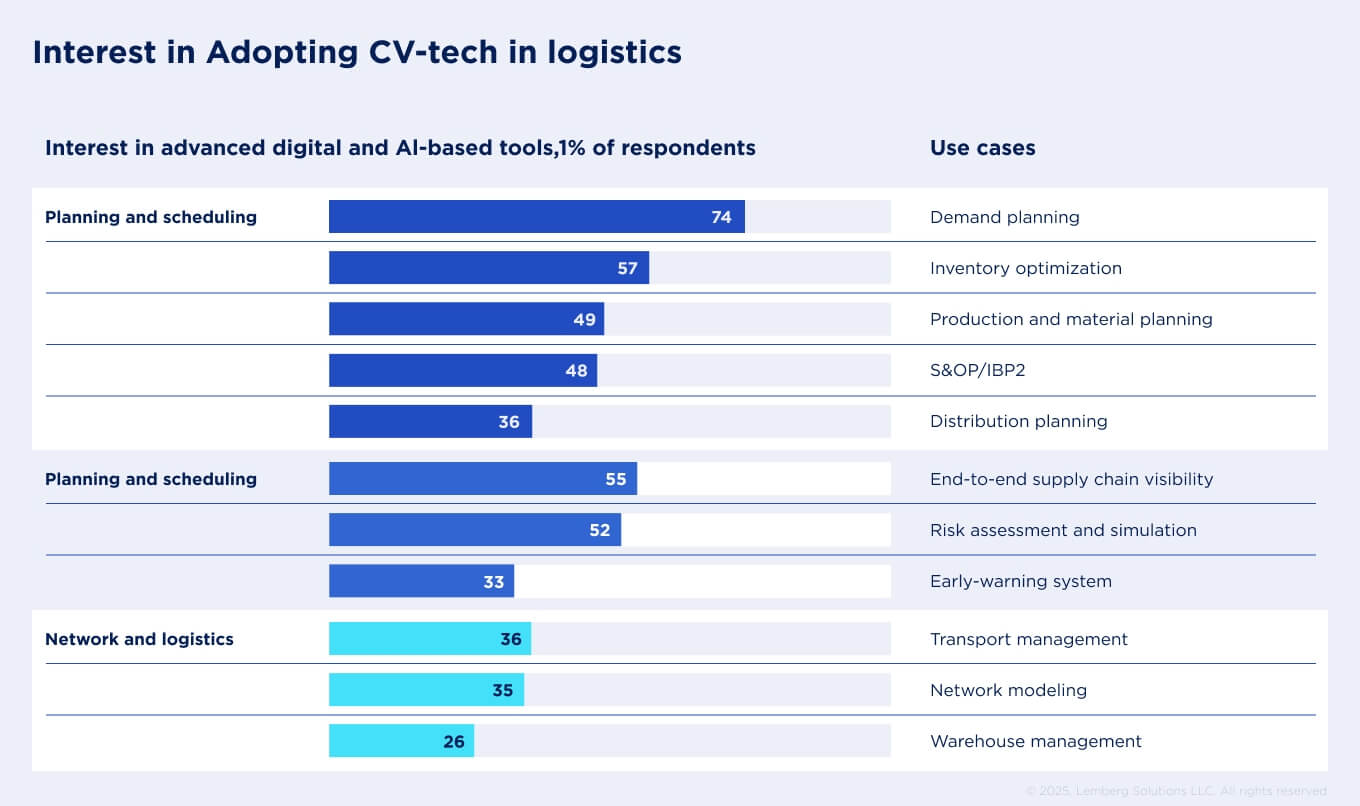

Unlike manual oversight, vision systems are easily scalable. Adding more cameras or expanding zones doesn’t proportionally increase error risk in the same way that adding more human checkers would. And this scalability reinforces CV adoption across businesses. McKinsey reports that 55% of supply chain leaders plan to increase investments in AI tools to improve end-to-end visibility. Meanwhile, 36% are prioritizing AI for transport management and network modeling, and 26% for warehouse management.

Real-world use cases: where computer vision delivers the biggest value

Defect identification & sorting

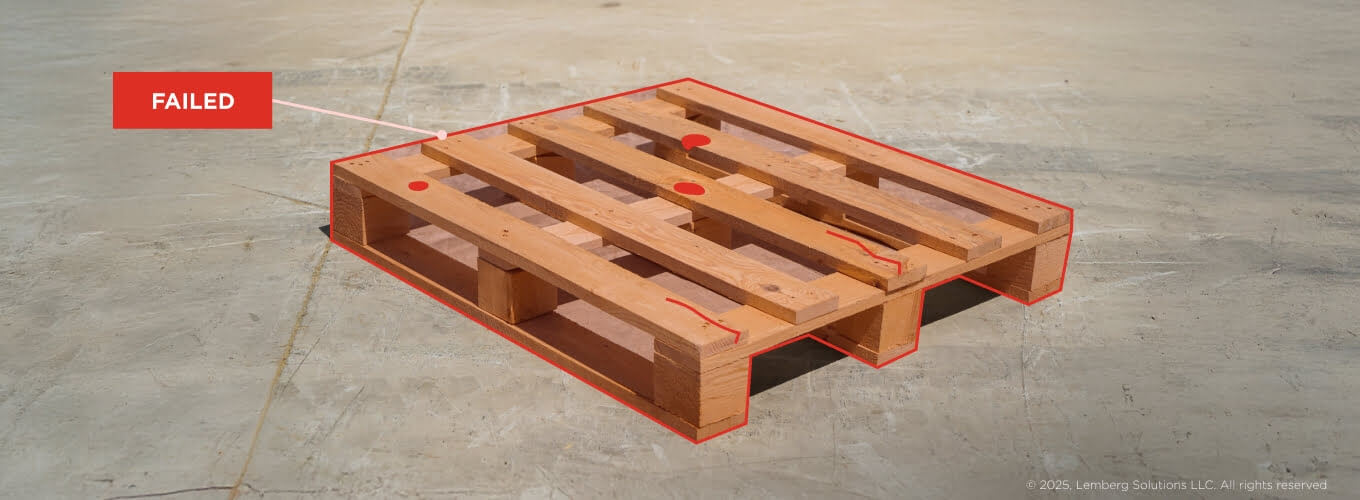

Not so long ago, defect detection in warehouses and logistics relied heavily on 24/7 manual labor. Today, CV-tech is seen as an effective complement to Gemba Walk, helping managers not only gather observational and interactional information but also identify the cost of asset damage and repair, as well as streamline maintenance processes.

For instance, Ivisys’ defect identification solution, Pallet AI, enhances the quality inspection process of pallets, identifying defects such as cracks, holes, mold, and discoloration. Utilizing a network of cameras and AI-driven pattern recognition techniques, the system is capable of inspecting a range of 250 to 450 pallets per hour.

Asset counting and localization

A familiar challenge inside the warehouse is pallets, cages, trolleys, and other assets going missing. In such cases, computer vision is used to count and locate assets by assessing their status in real time.

For object counting, deep-learning algorithms detect and classify objects in an image or video stream, identifying and analyzing image focus points and repeating this process to count all instances of a specific object. Then, an algorithm analyzes this input to estimate and trace the asset’s path throughout the warehouse. The CV-powered platforms, such as one developed by startup Kibsi, utilize existing camera networks to track assets and monitor activity within a warehouse. Assets can be georeferenced on a virtual map, and warehouse operators can locate assets with accuracy to within an inch.

CV-based driver support

Driver fatigue is a common problem in long-haul trucking, often resulting in missed signals, delayed reactions, or lane drifting. Here is where computer vision technology proves useful. For CV driver support, cameras and AI-based recognition algorithms monitor eyelids and facial expressions for signs of fatigue, alerting drivers to take breaks and signaling potential danger to other road users. The same technology can be used to detect and issue warnings about correct seat belt use and unauthorized personnel entering the vehicle.

As an example, Cipia, an Israel-based company specializing in in-cabin sensing solutions for the automotive industry, already leverages the advantages of CV-based driver support for in-car and in-cabin automotive environments. Its portfolio includes driver and occupancy monitoring systems designed to strengthen awareness inside the car and reduce risks on the road.

What ROI can supply chain leaders expect from computer vision

Implementing CV-tech in warehouse and logistics operations can yield strong returns by cutting errors, returns, and labor expenses. For example, 58% of organizations investing in vision AI report higher operational efficiency, and 48.19% are experiencing cost reductions. Furthermore, companies that adopt computer vision report 24% faster delivery time and improved inventory accuracy with ROI realized in weeks rather than in months.

Real-time visual monitoring ensures mis-picks and packing errors are caught before shipping, reducing costly returns and boosting customer satisfaction. Labor costs drop because fewer staff are needed for manual checks. Over time, the system also builds rich visual “ground truth” data that enables process improvements, traceability, and predictive insights.

How to integrate computer vision with your existing systems: ERP, WMS

Computer vision is designed to work alongside your ERP (Enterprise Resource Planning) and WMS (Warehouse Management System), not replace them. However, these systems are only as good as the data entered into them. Too often, that data comes from manual checks, barcode scans, or spreadsheets, all prone to human error. Integration of computer vision eliminates this weak link by capturing and verifying information automatically, then updating the ERP/WMS in real-time.

- The section below outlines the steps for integrating a computer vision solution with your ERP/WMS:

- Identify which processes (inventory counts, loading checks, quality control) depend most on manual data entry.

- Deploy cameras in key areas. These may include shelves, conveyors, and loading docks.

- Ensure the captured images are analyzed by AI either on a small on-site server for real-time response, or in the cloud for centralized control.

- Apply APIs or middleware to transmit your data into your ERP or WMS, keeping the system of record up to date without manual input.

- Ensure the ERP/WMS updates automatically with collected data. Inventory levels, order statuses, and audit logs stay accurate without extra manual checks.

- Start with one area (e.g., outbound loading) and expand coverage as ROI becomes clear.

Implementation: from PoC to full-scale deployment

Adopting computer vision in logistics is not a set-it-and-forget-it event. Most companies start small, prove value in one area, and then scale across the warehouse. Here’s what a typical journey looks like:

Discovery & camera setup

The first step is to identify where human errors cost you the most. This depends on your business, but the most common are receiving docks, picking lines, or quality control stations. Cameras are then installed in these zones, with attention to lighting and placement, so the system can “see” clearly.

Data collection & labeling

A computer vision system needs examples of what the “normal” and “incorrect” activities are to train. During this stage, images of pallets, boxes, barcodes, and defects are collected and labeled. This provides the foundation for teaching the AI to recognize both routine and exception cases.

Model training & testing

Engineers train computer vision models on labeled data and test early versions on real samples to evaluate accuracy and speed. Then, they fine-tune the model to reduce false alarms and missed detections, ensuring stable performance in daily use.

Algorithm development & fine-tuning

Beyond simple recognition, engineers develop CV algorithms to catch complex situations, such as overlapping packages, misaligned labels, or damaged goods. The goal is to build a system that can handle warehouse realities, not just lab conditions.

Integration with ERP/WMS

Once reliable, the vision system is linked to your existing software. Through APIs, the AI automatically updates your ERP/WMS with verified inventory counts, movement data, or error alerts, eliminating manual input and ensuring your systems remain the single source of truth.

Pilot & dashboards

Before implementing the computer vision system on the whole warehouse, it is reasonable to launch a pilot in a limited zone. Managers then monitor real-time dashboards that show error rates, throughput, and accuracy improvements. This allows leadership to measure ROI before committing to full rollout.

Support, monitoring & retraining

Computer vision is not a “set and forget” tool. As your business introduces new SKUs, changes layouts, or faces new conditions, the model may need retraining. Ongoing monitoring and vendor support ensure the system continues to deliver accurate results over time.

Final thoughts: why now is the right time to adopt AI-powered visual intelligence

AI-powered computer vision offers a scalable way forward. This is where AI-powered computer vision comes in as a scalable way forward.

Early adopters are already seeing ROI in weeks, not months, through sharper visibility, lower error rates, and happier customers. The takeaway is clear: waiting means falling behind. Companies that invest in computer vision today will not only cut costs and reduce risks, but also build the resilient, data-driven logistics operations that tomorrow’s supply chains demand.