Enhancing Voltfang's energy storage systems with an IoT telemetry solution

About the client

Voltfang is a German company delivering sustainable energy storage solutions using second-life batteries in electromobility since 2020. The company enables efficient renewable energy storage, reducing the ecological footprint.

The challenge

Voltfang was looking to optimize the performance of their energy storage and introduce real-time monitoring of their storage systems. Voltfang reached out to us with the following requests:

Delivered value

Solution

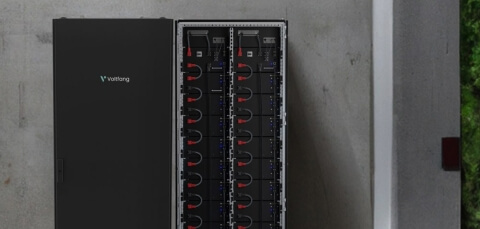

The Lemberg Solutions team built an IoT solution that collects data from six master BMSs within the energy storage system and transfers it to the cloud environment. The delivered product helps Voltfang create more efficient and stable energy storage systems for their customers.

Check out the features and functionalities of the IoT solution we delivered:

- A robust firmware maintaining stable communication with battery management systems through six CAN channels.

- Connection to the cloud environment. Our engineers integrated the IoT device to the cloud using AWS IoT Device SDK, enabling remote battery monitoring.

- OTA functionality for the firmware ensuring seamless updates, security, and uninterrupted operation.

- Fully-functioning hardware prototype — our engineers debugged and brought up the prototype provided by Voltfang.

- XMC4700 microchip. Lemberg Solutions engineers selected and integrated the Infineon XMC4700 MCU microchip since it can withstand the load of six CAN channels simultaneously. It’s also the number one pick for motor control and EV charging due to its robustness and efficiency.

How did we make the product development more efficient?

To simplify the development process and reduce the delivery time, we built the IoT solution within the DAVE 4 IDE designed for Infineon XMC devices. It was possible as the DAVE environment offers component-based programming and GUI configuration, while XMC libraries and DAVE example applications provide ready-made solutions for specific modules.

Before testing the product, our embedded engineers ran the software through a static code analyzer to ensure the solution was safe and secure. After that, QA engineers tested the product to ensure it met Voltfang’s requirements and was ready for market release.

Lemberg Solutions delivered great work with impressive speed in both development and testing, demonstrating excellent problem-solving skills. Their communication was consistently clear and effective, ensuring a smooth project flow. The team's overall capabilities helped us realize our IoT project in time for both software and hardware.